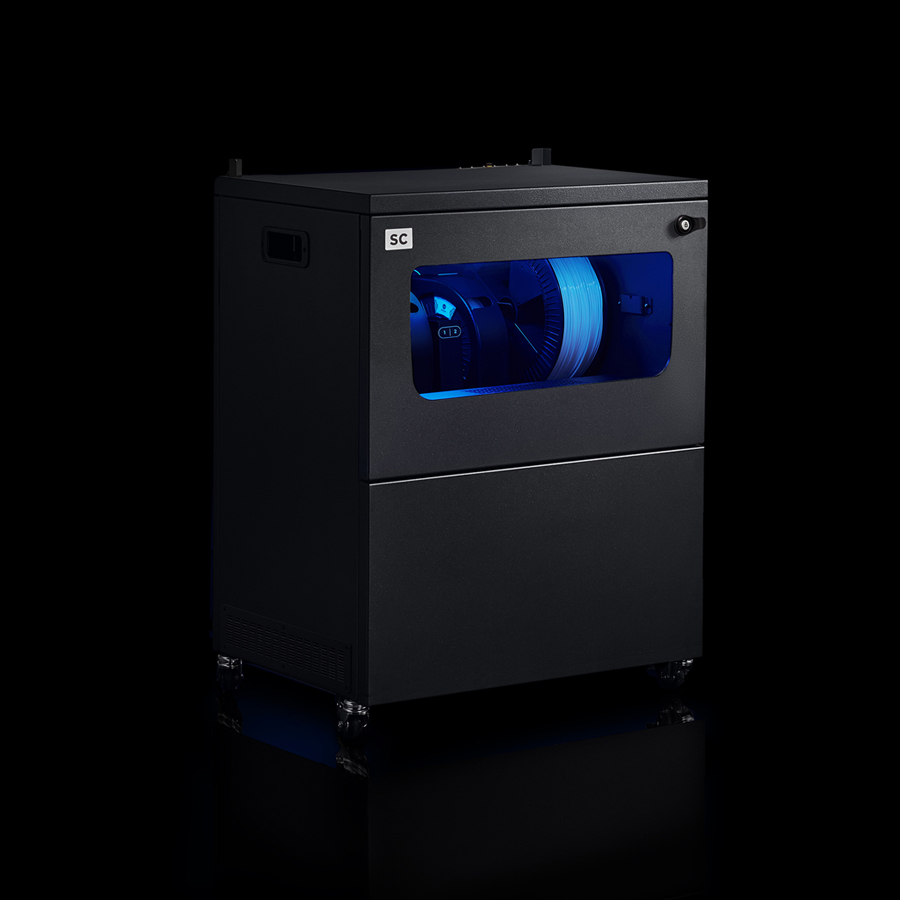

BCN3D SMART CABINET

Discover the Smart Cabinet - the most efficient partner for your BCN3D printers

On-demand webinar: Three ways in which the Smart Cabinet boosts your workflow

Performance

Supported by our smart drying technology, the humidity-controlled environment has been designed to extend the service life of your materials, protecting the filament and reducing print failure due to moisture, significantly improving your prints’ quality.

The mechanical properties of the 3D printed part are strongly dependent on how well the filament is stored

Tensile specimen printed in Polyamide (PA) from a spool stored in a regular environment.

Tensile specimen printed in Polyamide (PA) from a spool stored in the Smart Cabinet.

+ 22% Tensile Strength. + 57% Young's Modulus of rigidity.

Our Smart Drying Technology

Within our humidity-controlled environment, an automatic drying cycle pushes the air through a compartment filled with alumina, a material that absorbs the moisture.

The desaturated air is pushed back towards the material compartment, free of any moisture that could damage your filaments. This cycle reduces significantly the environment’s relative humidity.

This technology effectively keeps the filament dry, ensuring that the materials maintain their mechanical properties throughout the whole 3D printing process.

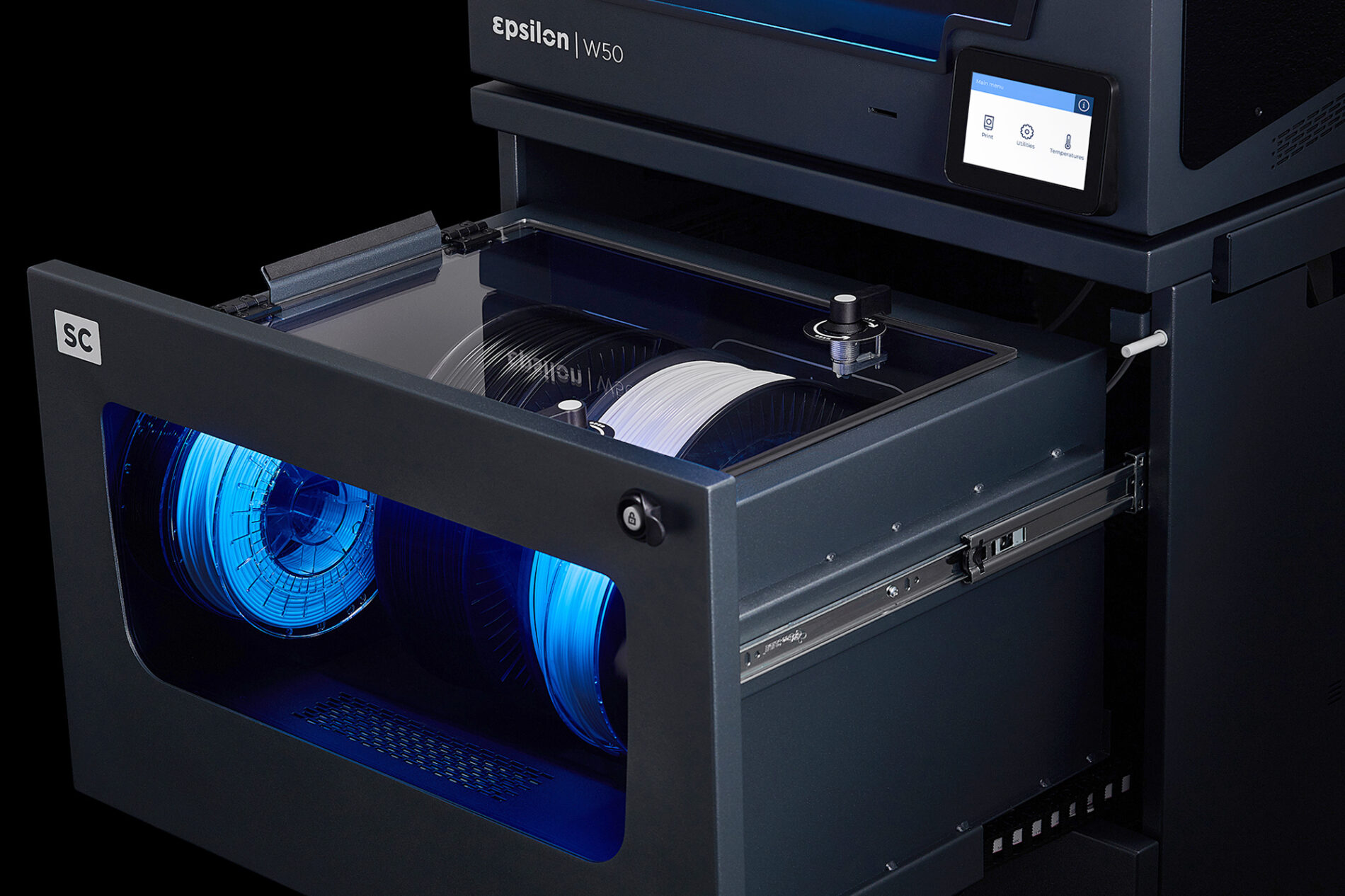

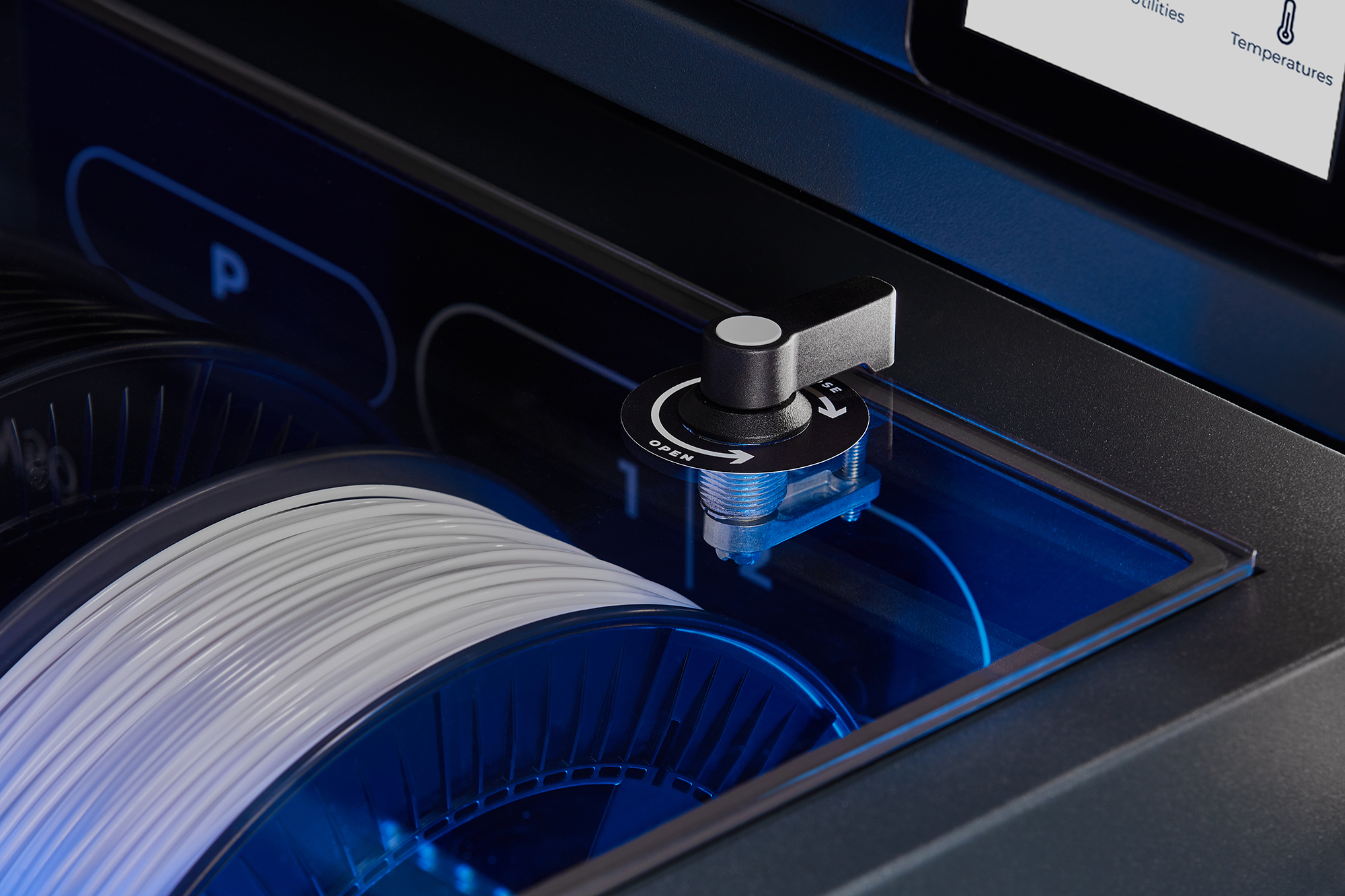

BCN3D Spool Cartridge

The new BCN3D Spool Cartridges have been designed to give you greater control during the process of loading and unloading filaments, while significantly accelerating both workflows.

BCN3D Spool Cartridge

The new BCN3D Spool Cartridges have been designed to give you greater control during the process of loading and unloading filaments, while significantly accelerating both workflows.The magnets in their cover and the main body allow for easier loading of spools, as well as to quickly snap the cartridge in the loading or parking area of the Smart Cabinet. This system also prevents filament tangling: when unloading your material, the extra slack due to the long distance between the extruders and print heads is kept inside the cartridge.

White paper: The effects of humidity on 3D printing filament and drying methods

Get the best finish

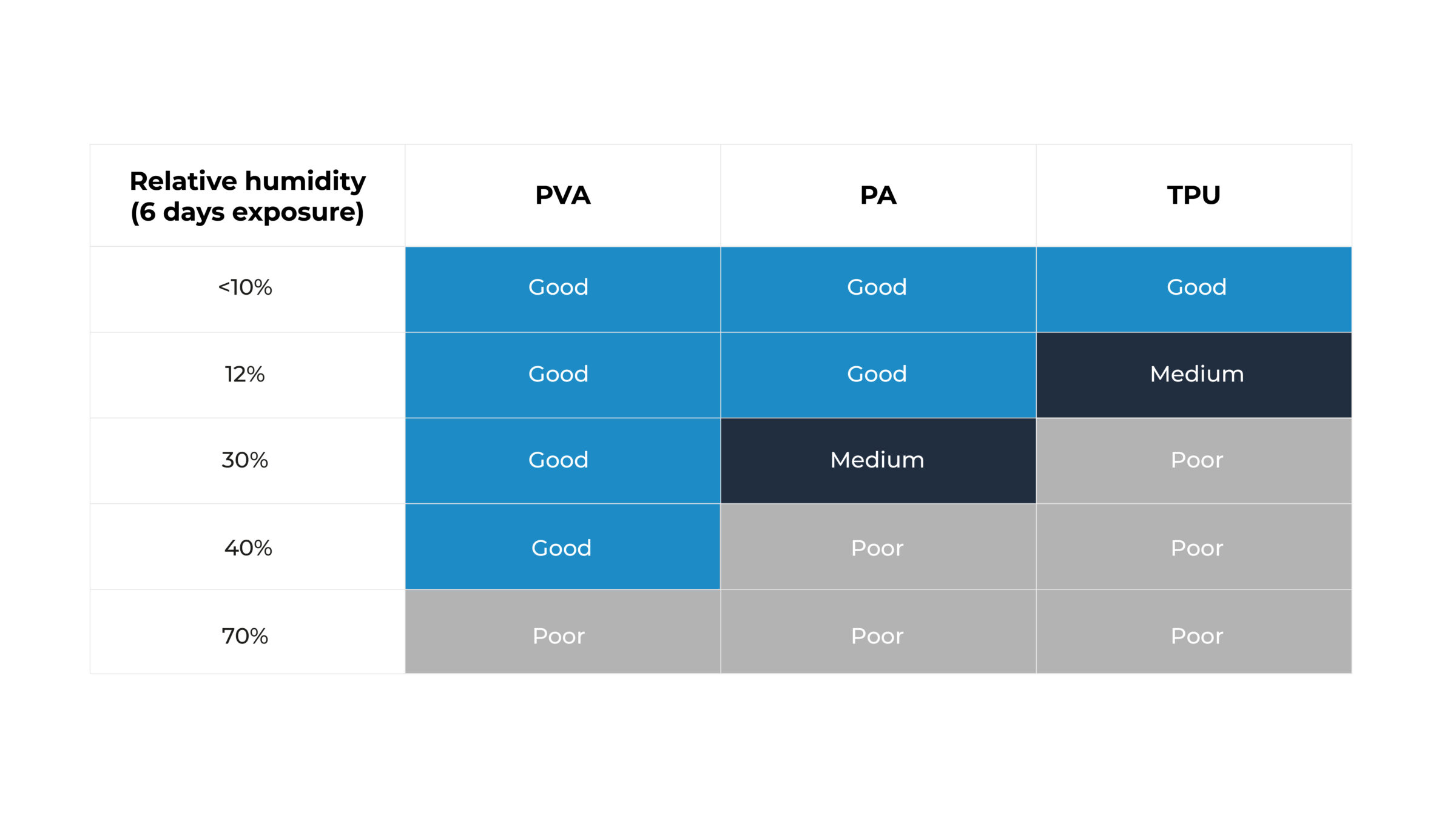

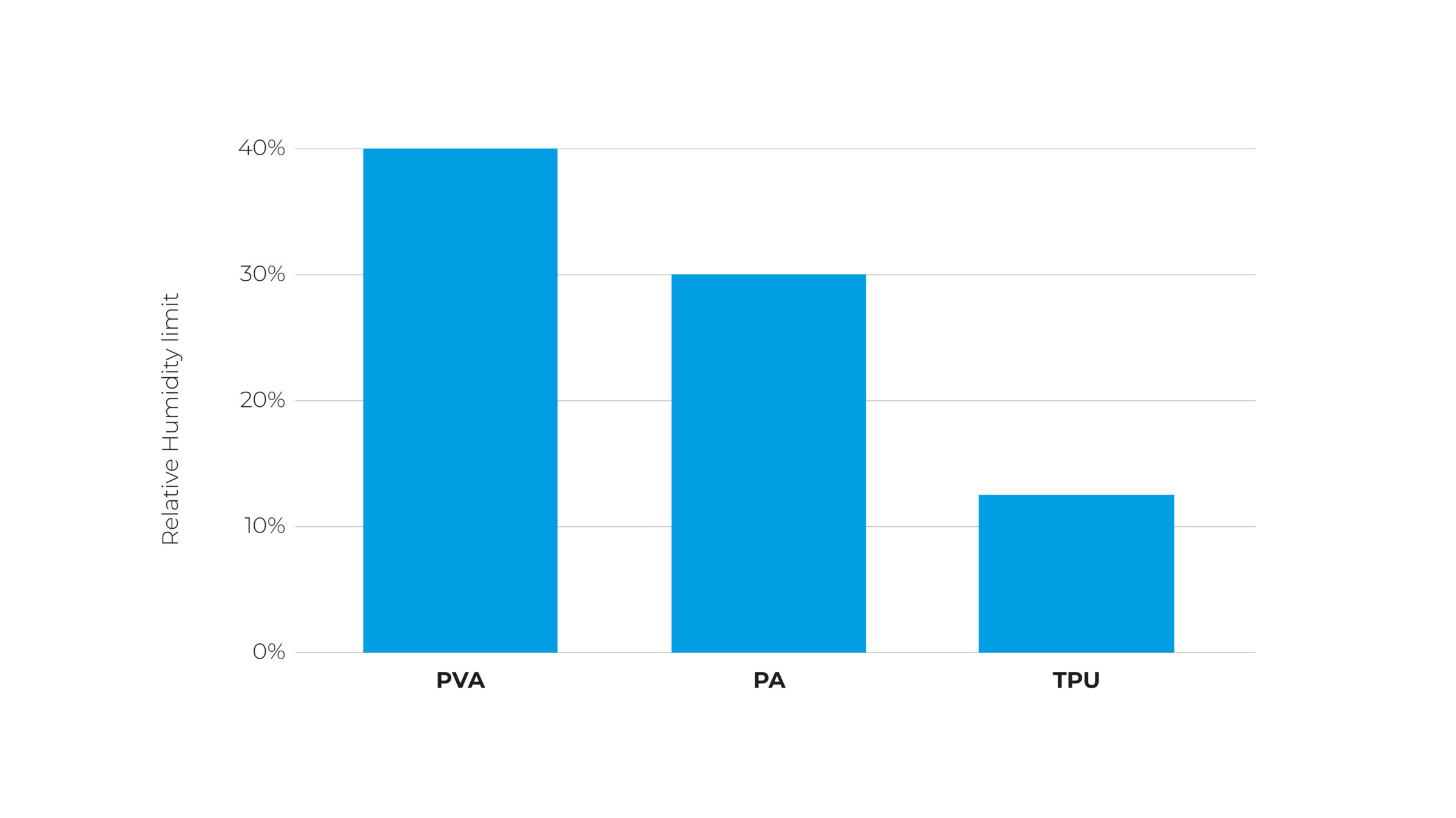

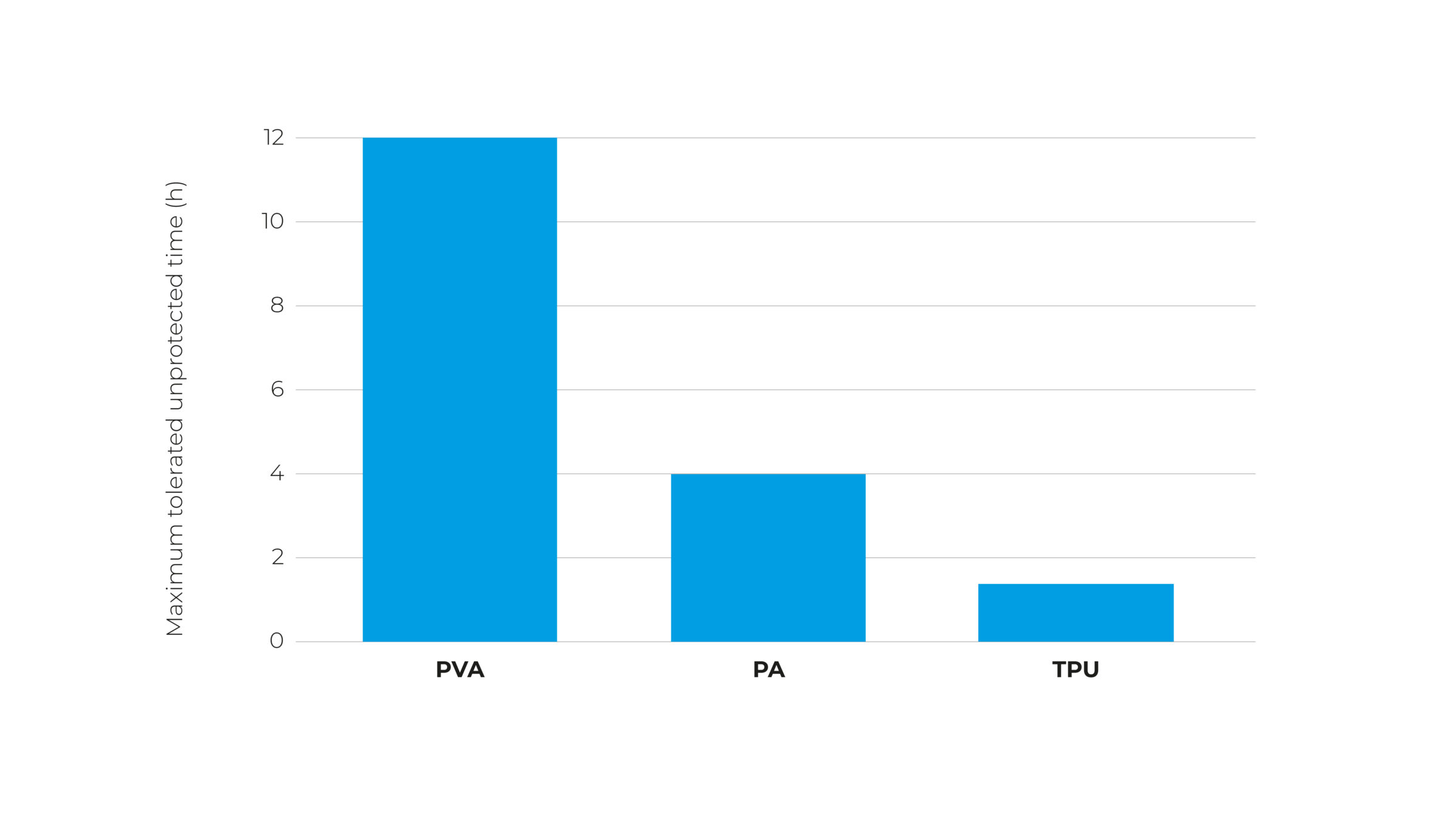

Hygroscopicity, the tendency to absorb moisture, is a great enemy of 3D printing, as it is a prominent characteristic of most thermoplastic materials. Even a small percentage of humidity can negatively affect most filaments and, therefore, the end result of the print job, not only through imperfections which appear on the print surface, but also damaging its mechanical properties. Correctly storing your filament will have, then, a significant effect in the overall quality of your printed parts.

Tested Sample: BCN3D PA (polyamide)

Spool stored 4 days in an environment with high levels of humidity. Over extrusion and poor accuracy. Rough surface, opaque appearance and much stringing are an indication of an irregular extrusion and poor interlayer adhesion.

Spool stored 4 days in a workspace environment with 40-60% relative humidity. Good extrusion and dimensional accuracy, but rougher surface, due to the formation of vapor micro-bubbles.

Spool correctly stored in the dehumidifier of the BCN3D Smart Cabinet. Continuous extrusion without interruptions or formation of vapour bubbles. Smooth surface and no stringing.

Spool stored 4 days in an environment with high levels of humidity. Over extrusion and poor accuracy. Rough surface, opaque appearance and much stringing are an indication of an irregular extrusion and poor interlayer adhesion.

Spool stored 4 days in a workspace environment with 40-60% relative humidity. Good extrusion and dimensional accuracy, but rougher surface, due to the formation of vapor micro-bubbles.

Spool correctly stored in the dehumidifier of the BCN3D Smart Cabinet. Continuous extrusion without interruptions or formation of vapour bubbles. Smooth surface and no stringing.

Benefits of the Smart Cabinet compared to other drying methods:

BCN3D Smart Cabinet:

- Optimal for all materials

- Low Energy consumption: 12 W Avg / 100 W Max

- 10 storage slots for small filament spools (4 for big spools)

- Prints while in dry storage

- Humidity-controlled environment, dries without heat

- No consumable parts

Other systems:

Oven Baking:

High energy costs, decreases tensile strength, time-consuming, melts filament if too hot.

Desiccants:

No RH control, constant replacement, and maintenance.

AC & Dehumidifier:

High energy costs, unable to reach below 40% RH, ineffective in low temperature/winter conditions.

Other Filament Dryers:

Constant heat baking with high energy consumption, unable to dry for extended periods, only able to dry a few spools at a time.

Questions? Check out our FAQ document and find every answer you'll need!

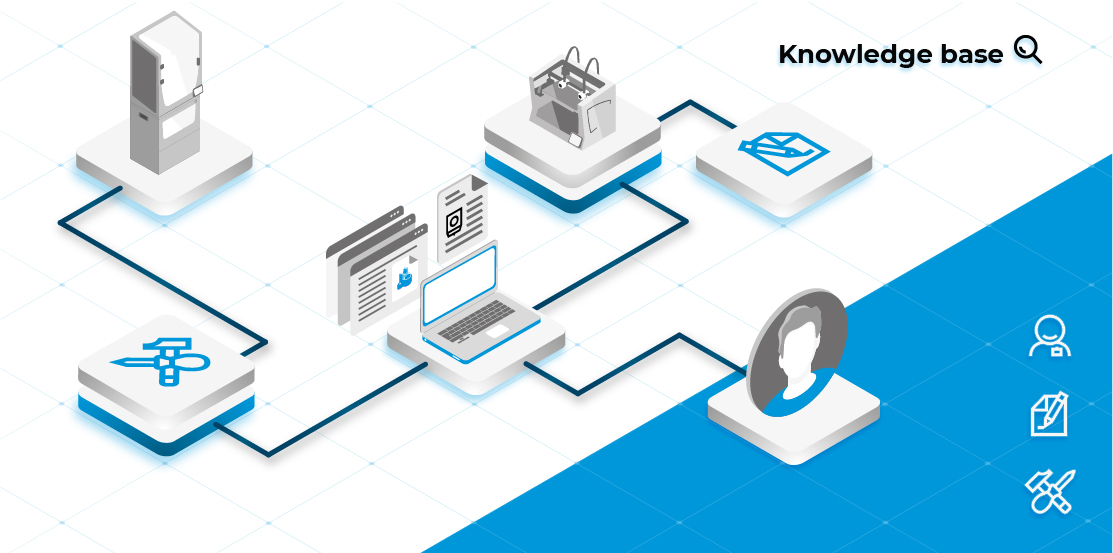

Maximize the use of your 3D printing equipment

Get the most out of your BCN3D machinery thanks to our Knowledge Base, an ever-expanding repository of tips and tricks sourcing directly from our 3D printing experts in order to help you boost your equipment’s performance.

Knowledge Base