SJD Barcelona Children’s Hospital prints anatomical models for the planning and simulation of complex surgeries

Pioneers in the research and implementation of new technologies, SJD Barcelona Children’s Hospital employs the use of 3D printed anatomical models for the planning and simulation of around 200 surgeries per year. Using BCN3D Epsilon W50 and Sigmax printers, 3D printed biomodels of a tumor, the surrounding skull, and the required implants that followed were created for a resection procedure. We speak to the radiologists, oncologists, engineers, and surgeons that contributed to the success of this case.

No matter the severity of any given surgery, each one carries its own risks and regulations. For private, non-profit SJD Barcelona Children’s Hospital, 3D printing is helping cater to the pediatric and maternity needs of the public in around 200 surgeries per year. We paid a visit to the collective team of surgeons, engineers, and more to discuss a specific case in which a biomodel for an oncology case was used for 3D planning and the surgery itself. We follow the case from the radiologist’s first impressions to the outcome for the patient himself.

Stepping into SJD Barcelona Children’s Hospital

Number 3 in terms of activity in Europe and number 1 for activity in pediatrics in Spain, SJD Barcelona Children’s Hospital doubles as a university hospital, carrying out research, innovation, and education. With animal-themed corridors, interactive pieces, and live music flowing throughout the reception, everything is directed at making the patients as at peace as possible.

The exponential expansion of 3D printing

3D planning and printing made their way into the hospital in 2013 after Dr. Lucas Krauel specifically requested a biomodel to complement the planning of a complicated oncological case. From there, the use of this technology expanded exponentially, resulting in the creation of a multidisciplinary group.

“Nowadays, we have more than 200 surgeries planned with 3D printing and 9 different specialties that are benefiting from this technology.” – Arnau Valls, innovation engineer and technical manager of the 3D printing unit at SJD Barcelona Children’s Hospital.

SJD Barcelona Children’s Hospital’s 3D unit, the 3DForHealth (3D4H), was then officially established in 2016 thanks to the work of radiologists, surgeons, engineers, and financial and simulation experts. By enabling the 3D planning, virtual simulation, and creation of 3D printed anatomical models and cutting and positioning guides required for complex surgeries and custom implants, it provides for needs across all pediatric specialties. Its actions cover a wide basis of education, R&D projects for new devices, developing simulators for specific needs, and more. This 3D unit is the first in Spain to be credited by the Generalitat de Catalunya for the quality of its in-house printing.

The case at hand

For this particular patient, he’d already undergone surgery that resulted in the removal of his left eye. Due to a predisposition to the development of other tumors, and despite rounds of radiotherapy and chemotherapy lasting 3 months, a tumor remained centered in the right maxillary bone. Since chemotherapy is not as effective in these types of tumors, it was fundamental for a complete resection to be carried out.

Of course, in complex surgery such as this, there are a number of key factors to be considered. Firstly, the affected area was the face, an obviously important part of the patient’s identity. Secondly, it is a growing child; the team had to take into account the growing stages of the skeleton that would follow. Lastly, the fact that the patient had lost his eye on the left-hand side meant keeping his right eye and sight was imperative.

The road to the resection

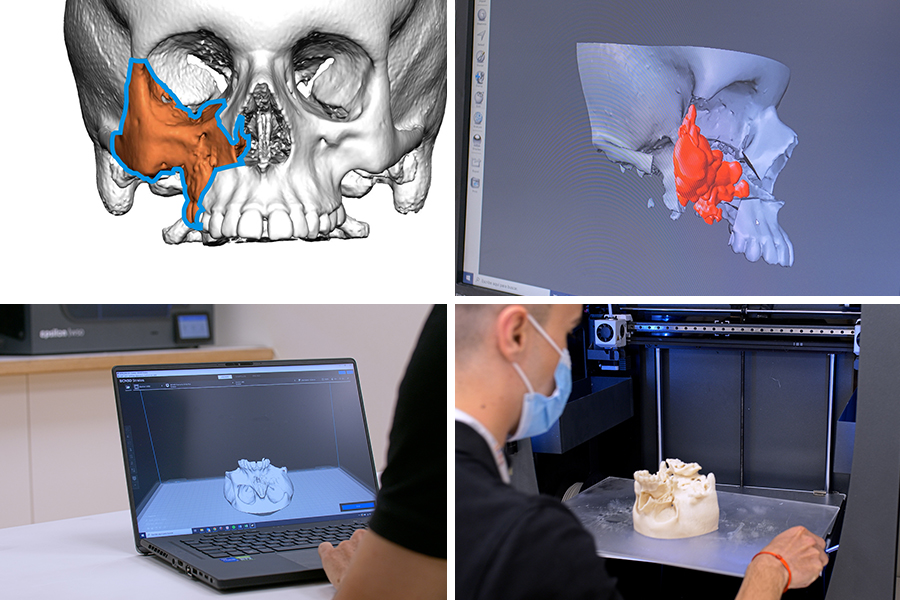

As a collective collaboration across all specialties, especially oncology and maxillofacial surgery, the process began with the use of imaging techniques (CT Scan and MRI) by radiologists to carry out tests for both the best diagnostic and the best protocols to follow. The findings were then compiled together with the preexisting information about this type of tumor. Not only is this stage crucial for evaluating and predicting the case, but it also played a role in planning for the aesthetic side of things.

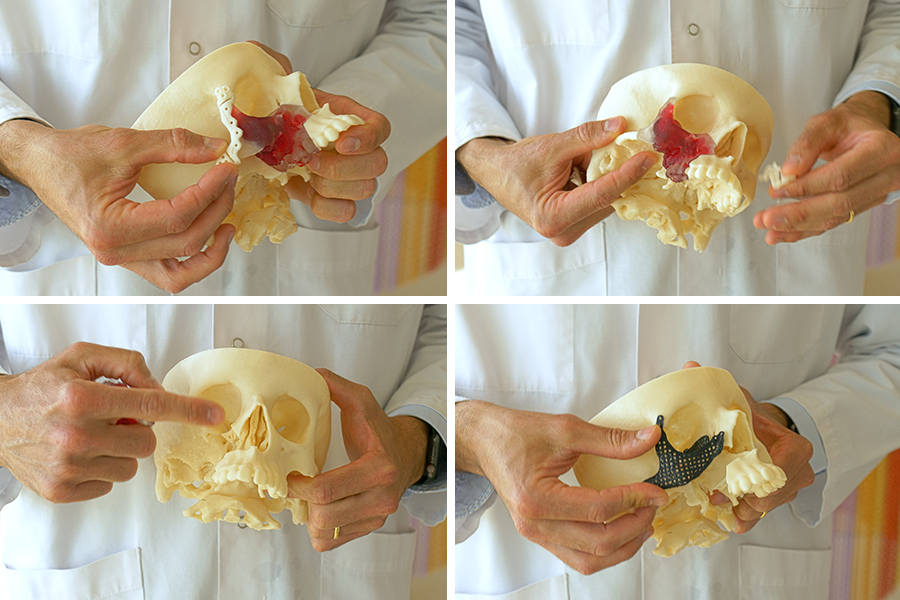

Next up, the radiologists, surgeons, and 3D printing engineers team came together to decide which aspects to print, create the elected segmentation in the CAD file, and begin 3D planning and simulation. Here, the group decided it was best to print different parts of the skull and the tumor itself. Prototypes of the titanium plates that were to be inserted were also 3D printed.

BASF’s ABS was chosen to replicate the color and anatomy of the bones. These biomodels serve as visual aids, portraying the anatomical relations between the tumor and the areas of the skull. The SJD team chose BCN3D printers for the realistic printing results that are the best for the price.

These 3D printed parts mean the doctors can verify the implants will fit the patient. Acting as a means of strict quality control, they can also simulate the surgery itself, define the limits of the incisions for the surgery, and practice the cuts they need to make.

On the day of the surgery itself, both images and the physical biomodels themselves could be found at arm’s length for reference. Having this planned outcome gives the doctors a point of reference to work from and added confidence.

“3D printing helped us to avoid possible post-operative surgeries and improved the quality for both the patient and the surgical process.” – Dr. Adaia Valls, maxillofacial surgeon at SJD Barcelona Children’s Hospital.

“The truth is that initially, it was a little complicated because it’s concerning the face. We were wondering whether there would be a lot of scarring … but the surgery truly went really well and the scarring is minimal. From here, we keep moving forward and follow the marked protocol.” – Klever, father of the patient.

The smooth running of this surgery and the reflection of the experience from the patient himself is a testament to the team at Hospital SJD. 3D printing is a key player in the advancement of medical models becoming increasingly more accurate; the 3DForHealth lab will proceed to, together with the combination of new technologies, improve the creation of patient and surgeon-specific guiding and positioning tools. Furthermore, the team aims to better mimic living tissues through researching mechanical properties, colors, and textures. Another area for development is that of bioprinting, where printed parts act as a solution directly for the patient and 3D printed pharmaceutical products that can be personalized. It’s clear that 3D printing has and will continue to make an impact on the way we approach medicine.