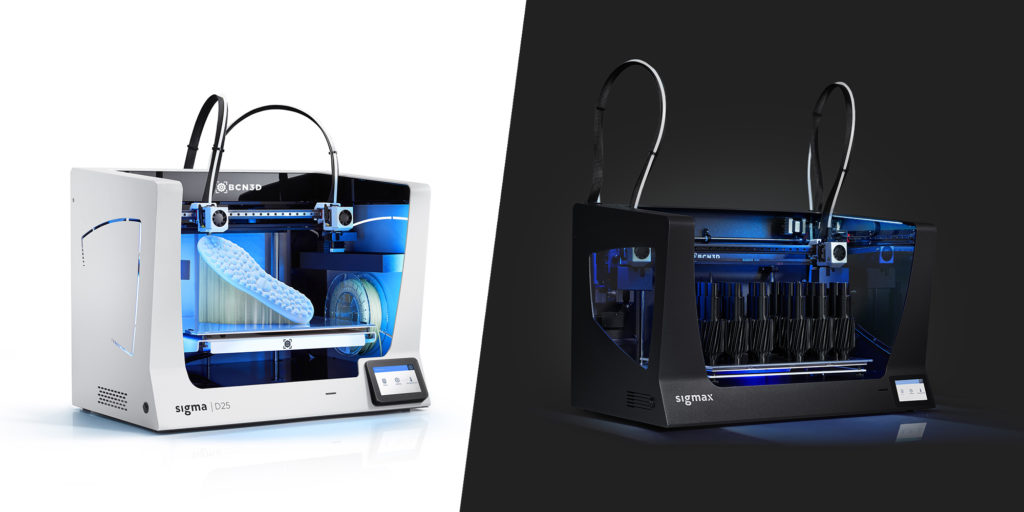

Sigma D25 vs Sigma(x) R19: An in-depth explanation of the improvements implemented on our signature Sigma line

We thrive on innovation; we are continuously working on improving our users’ 3D printing experience, and we do so through a process of constant refinement of our products and solutions. A good example of this is our signature Sigma line, which has evolved significantly over time. The latest generation of this Series takes form in the Sigma D25, a 3D printer that includes various advances compared to its predecessor, the Sigma R19. Keep reading to find a detailed explanation of everything that is new!

In the time between the launch of the Sigma(x) R19 and the Sigma D25, there had been a lot of major developments that took place within the BCN3D Epsilon Series. Now, many of these improvements are being brought to the Sigma Series, mainly in the form of refined reliability and an enhanced user experience.

One of the most obvious changes that have taken place affects the volume, letting go of the smaller Sigma size and choosing to continue with a more competitively sized Sigmax R19-like build volume. After careful consideration, we came to the decision that this was a much better platform to utilize the benefits of IDEX, with a much larger X-axis compared to the previous Sigma R19.

We at BCN3D also wanted to provide customers with a more affordable platform, optimized for the most-used, standard materials in the desktop market, which are easier and safer to print for at home or in an office. This eliminated the need for the specific components that are required for supporting technical and composite materials, which had a direct positive influence on price. For customers that want to use technical and composite materials, the BCN3D Epsilon Series offers by default those components for creating high-quality parts with these more industrial-grade materials.

Main changes implemented on the Sigma D25 compared to the Sigma(x) R19

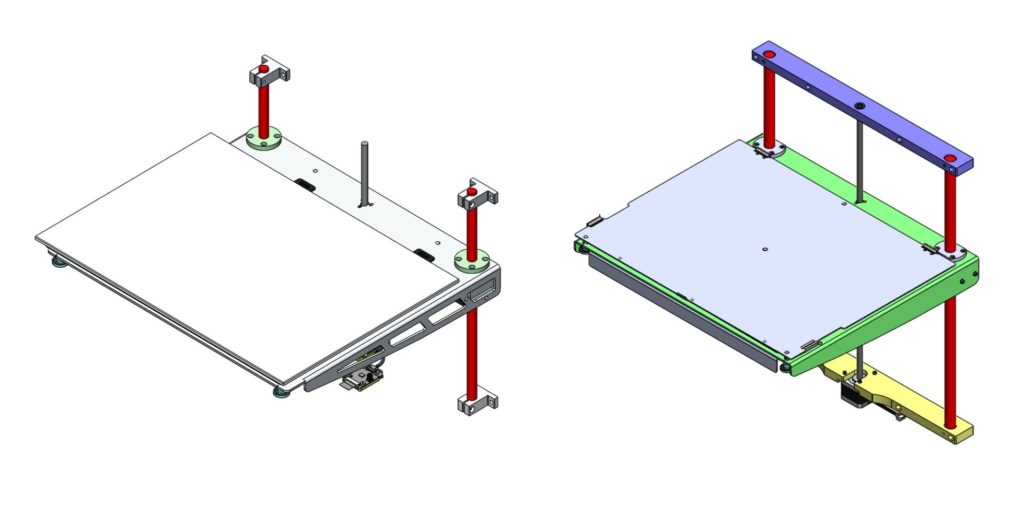

- Build platform and Z-axis assembly have been redesigned to include several improvements:

-

- Improved stiffness – more robust due to the redesigned Z shaft supports and lower bed platform.

-

- Better printing surface flatness – as a result of the new aluminum platform and improved bed clamps, same as in the BCN3D Epsilon Series.

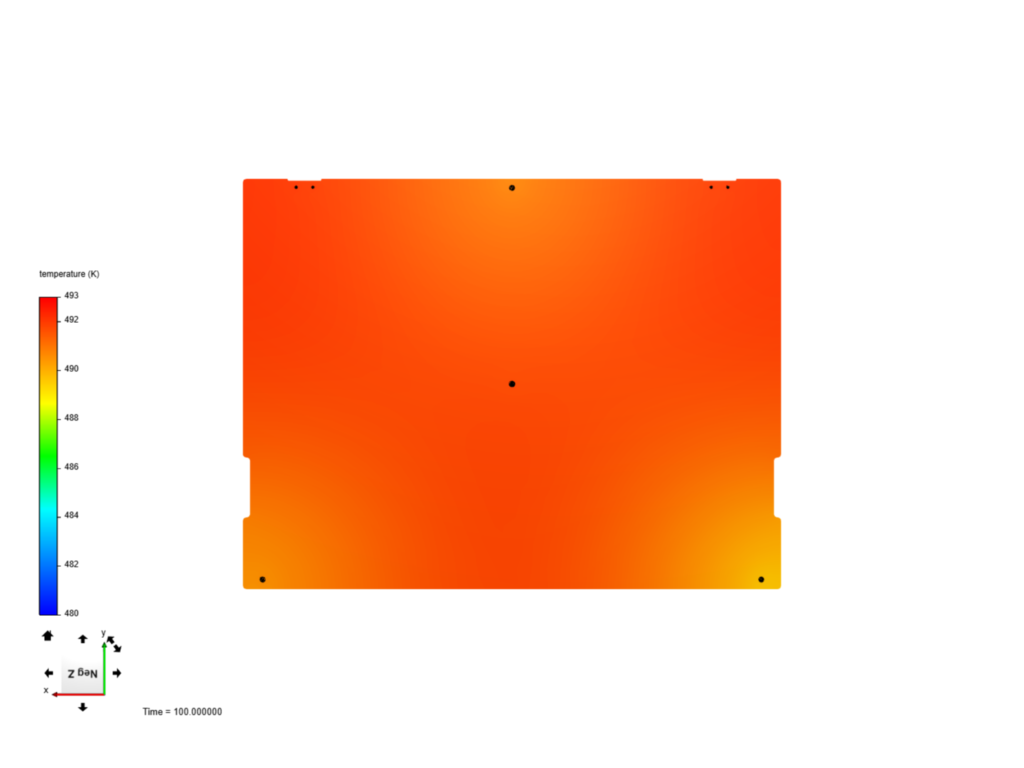

- Better heat distribution over the print surface – as a result of the new silicone thermal pad used instead of the PCB heater, eliminated air gap, and new aluminum platform, same as in the BCN3D Epsilon Series. In the picture below the heat distribution with the new platform can be observed, with a small spread of around 2ºC, compared to 20ºC from previous Sigmax R19s.

-

- Enhanced leveling procedure – with 30 microns adjustment accuracy and more ergonomic adjustment screws.

- Easier to assemble and repair – the Sigma D25 is assembled together as its own subassembly, which makes it more streamlined for technical services and repairs.

- Consolidated parts – same bed assembly and build footprint as the BCN3D Epsilon Series, as well as other general architecture components .

- Build volume – 420mm x 300mm x 200mm (25 Liters).

- Functionality:

-

- Standard Materials only – optimized to better support the most used materials in the desktop market: PLA, PETG, TPU, and PVA materials with BCN3D profiles, but still maintaining an open filament system to enable compatibility with third-party materials.

- 0.4mm and 0.8mm nozzles only – changed to support our customer’s two most used nozzles according to our usage data, allowing resources to be better spent on improving a focused selection of material profiles.

- 80ºC Max Bed Temperature – due to changes in the material offering, it was possible to reduce the cost of components to meet the less demanding requirements of standard materials.

- No add-ons required – due to changes in the material offering, it was possible to eliminate the need for add-on components like the enclosure and filtering.

- Electronics have been modified to improve stability, functionality, and UX to reflect the improvements made in the BCN3D Epsilon:

-

- Larger 5” touchscreen – for more comfortable user experience, like in the BCN3D Epsilon Series.

- Improved UI menus – more intuitive menus and UX, with multi-language support, like in the BCN3D Epsilon Series.

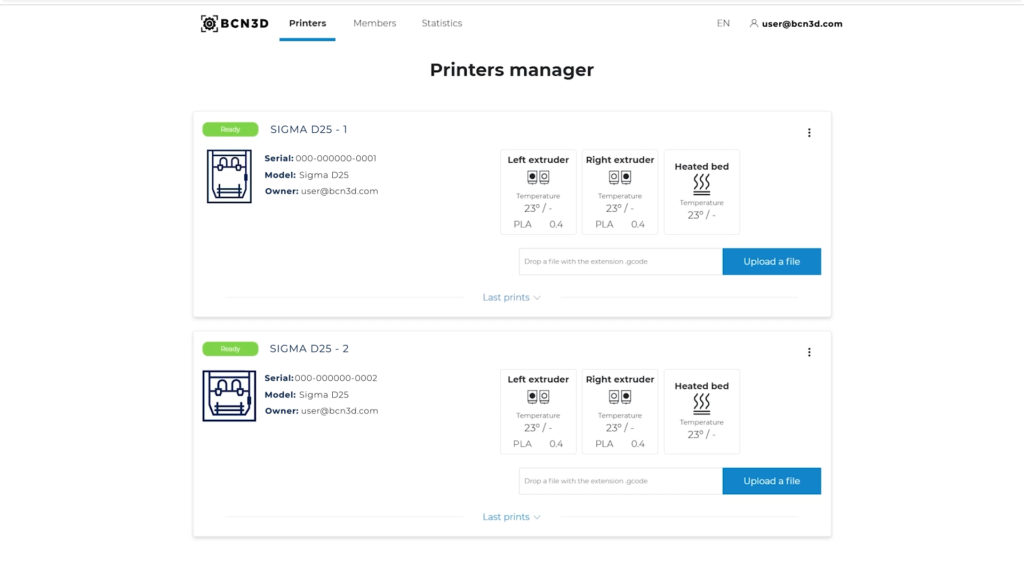

- Added Connectivity functionality– the Sigma D25 can now print over the network through WiFi or Ethernet, directly from BCN3D Cura or BCN3D Cloud.

- BCN3D Cloud Integration – the user can now also manage multiple printers, print jobs, and review print statistics, as well as printer setup through the BCN3D Cloud interface.

-

- Over-the-Air Firmware updates – due to added connectivity functionality.

- Updated calibration process – with optimized firmware calculations.

- Software/embedded– general improvements.

- Extrusion System:

-

- Improved Filament Loading – Filament Runout Sensor bracket design improved to eliminate issues during the loading process.

- Improved print profiles – overall improvement in print profiles and significant advancements for printing with PLA.

- Easier maintenance – extruders were moved to the backside of the printer to increase ease of maintenance.

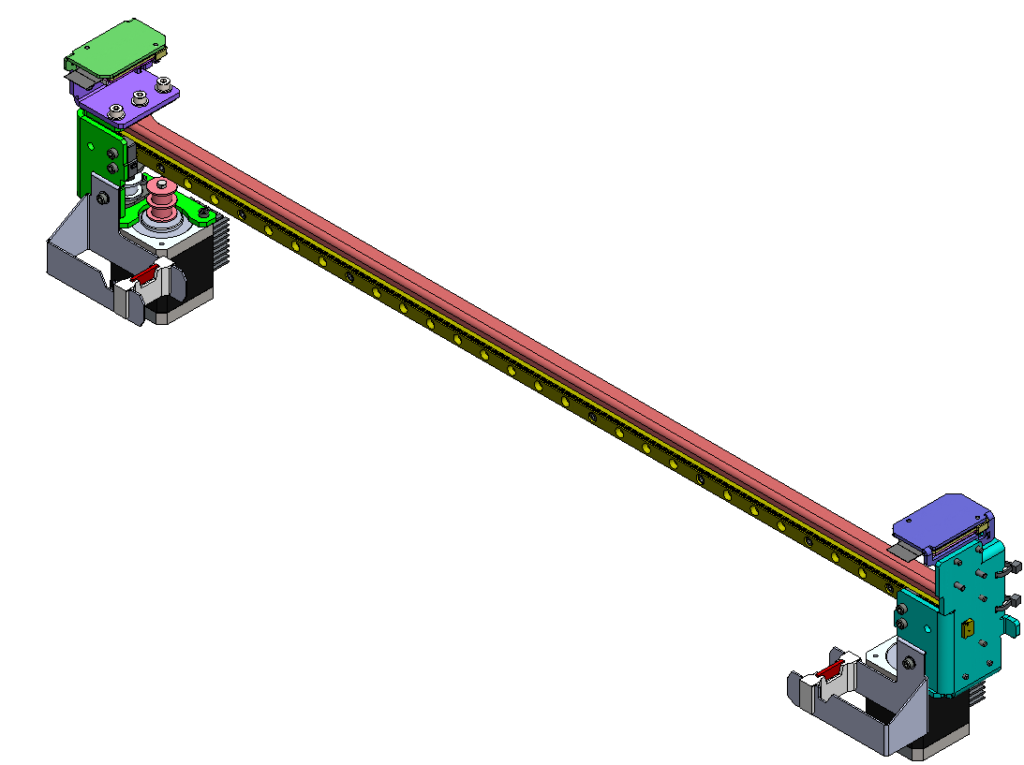

- Improved X-axis Assembly:

-

- Reinforced X-axis rail (the red bar in the illustration below) – now made of reinforced stainless steel instead of aluminium, same as in the BCN3D Epsilon Series.

-

- New motors – changed to NEMA17 motors instead of NEMA14, which were prone to overheating.

- Easier to assemble – improvements to the whole axis to greatly improve ease of assembly.

- Larger Purge Buckets: implemented larger, wider purge buckets that can handle much more primed filament, same as the Epsilon W27.

- Aesthetics:

- Taller welded Aluminium frame – due to changes in improved electronics and reinforced Z-axis.

- New Light Grey look – to differentiate itself amongst BCN3D’s growing product portfolio, create a more unique look for the future of the Sigma line, and provide a better fit in the desktop market.

As this blogpost demonstrates, the Sigma D25 presents significant changes compared with its predecessor, the Sigma/x R19, both inside and out, with improved user experience, reliability, and a reformed 3D printing experience in mind.

Interested in what this new generation of our best-known 3D printer can do for you? Reach out today!