BCN3D Omega I60: Deep dive into materials & applications for industrial demands

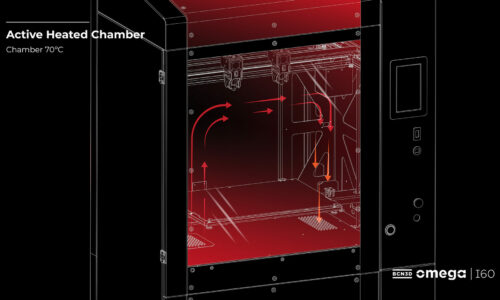

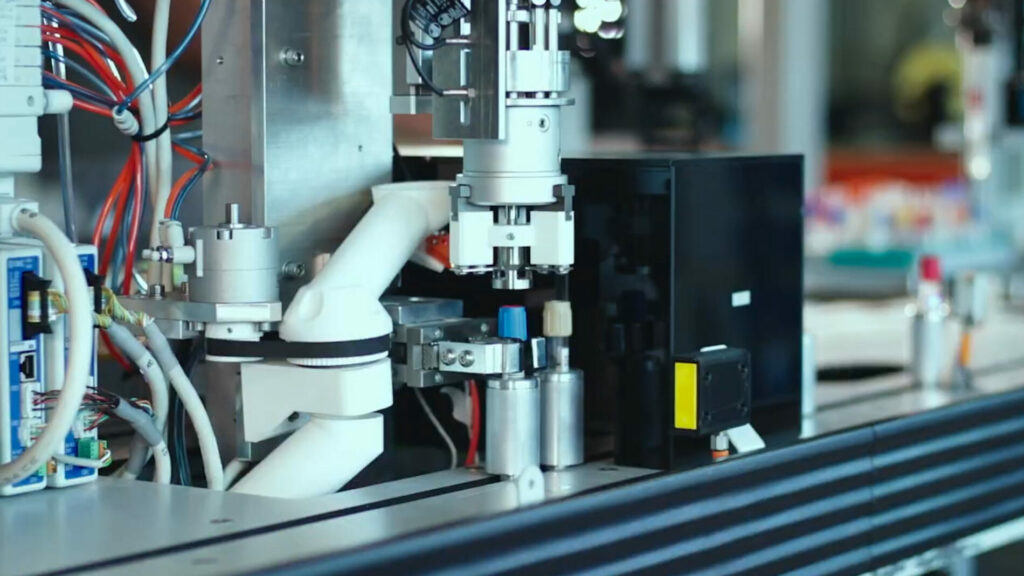

BCN3D Omega I60 is an industrial FFF 3D printer built for the factory floor designed specifically to produce large-scale, strong tooling, jigs, and fixtures. It has a wide range of features designed to take your 3D printing experience to new heights. In this blogpost, we invite you to explore the capabilities of BCN3D Omega I60 and delve deep into the potential of Omega Proto, Omega Tooling CF, and Omega Resistant Nylon to discover how these materials specially developed for this industrial machine can boost your projects. Among all its functionalities, the Omega I60, features an active heated print chamber, a custom motion system designed for precision and speed, and a revolutionary Material Operations System (MOS). The MOS eliminates concerns about filament humidity through active heating and humidity control, allowing for seamless filament switching and minimizing machine downtime.

The Omega I60 is a reality, available for under 20.000 eur and already shipping. Get in touch directly with us or contact your local BCN3D partner to receive your quotation.

Materials

Now, let’s dive into the materials meticulously crafted to complement the Omega I60:

- Omega Proto: First in line is Omega Proto, which is the top choice for functional prototyping, producing precise parts with a premium surface finish. Omega Proto stands out for its exceptional versatility, providing remarkable durability, toughness, and chemical resistance. It surpasses PLA in strength, is more user friendly than ABS, and delivers a surface finish superior to PETG. On top of that, Omega Proto offers great layer adhesion, creating stronger bonds between layers than what is achievable with typical prototyping materials.

- Omega Resistant Nylon: Omega Resistant Nylon is a custom copolymer of PA6 and PPA formulated especially for Omega I60 and designed for the most demanding manufacturing applications. This innovative material boasts exceptional resistance to chemicals, wear, and solvents, making it ideal for challenging environments. With superior heat deflection properties and printability surpassing traditional ABS and nylons, Omega Resistant Nylon sets a new standard for durability and performance in industrial settings. In fact, in terms of mechanical properties, it’s closer to Ultem™ 9085 than it is to standard FFF Nylon-based materials.

- Omega Tooling CF: Omega Tooling CF is a carbon fiber-reinforced PA6 copolymer filament designed exclusively for use with the Omega I60 printer. This specialized filament boasts remarkable strength, durability, thermal stability, and stiffness, characteristics you’d expect from carbon fiber materials. It excels in high-temperature environments, boasting a high heat deflection temperature (HDT) of 177ºC.

Applications

Now, let’s explore the specific applications where Omega I60 stands out:

- Jigs and Fixtures: When it comes to manufacturing, precision is a key factor. Omega I60 becomes the perfect ally for creating manufacturing fixtures with ease and speed. Whether low temperature applications like positioning fixtures or high temperature stress applications like welding fixtures, Omega Proto and Omega Tooling CF adjust to every need.

In other words, BCN3D’s Omega I60, combined with its revolutionary materials, marks a significant advancement in industrial 3D printing. It’s not just an industrial printer; it’s a solution that takes your projects to higher levels of precision and efficiency.

- Surface Treatment Masking: When we look at Omega I60’s applications, we turn our attention to surface treatment masking. A crucial step in processes like painting, powder coating, and chemical treatment. The Omega I60 shines in this area, providing a perfect solution for customizing masking components.

Traditional methods of production can be costly, and alternatives like tape can be time-consuming. For chemical treatments, Omega Resistant Nylon emerges as the ideal choice, boasting incredible resistance to chemicals and solvents. When it comes to high impact surface treatments such as shot blasting and powder coating, Omega Tooling CF takes the stage with its unmatched strength and impact resistance.

The Omega I60, combined with these advanced materials, streamlines surface treatment masking, offering efficiency and precision like never before.

- End of Arm Tooling: Transitioning to another critical application, let’s delve into End of Arm Tooling (EOAT) and how the Omega I60 is a game-changer in its design and production. 3D printing opens the door to rapid prototyping and customization of EOAT components, facilitating a swift and cost-effective iteration process. The flexibility provided by 3D printing allows for the creation of intricate geometries and lightweight structures, optimizing overall tooling performance while reducing payload. Traditional machined tooling often faces challenges in achieving such complexity and lightweight attributes. Here, Omega I60 and its advanced materials offer a cost-effective and efficient solution, aligning perfectly with the demands of modern automation.

In conclusion, these are many applications perfectly aligned with the capabilities of the Omega I60. However, considering the varied properties of the three materials launched alongside, and the promise of future materials including ABS, ASA, and ESD filaments, the potential applications are huge.

If you’re eager to learn more about the BCN3D Omega I60 or any of the materials highlighted in this journey, don’t hesitate to reach out to us. Our team of 3D printing experts is ready to guide you through the possibilities and help you harness the full power of BCN3D’s innovative solutions.

Thank you for joining us on this deep dive of the Omega I60, its materials and applications. Stay tuned for more exciting developments from BCN3D. Until next time!