Technology

What is 3D Printing?

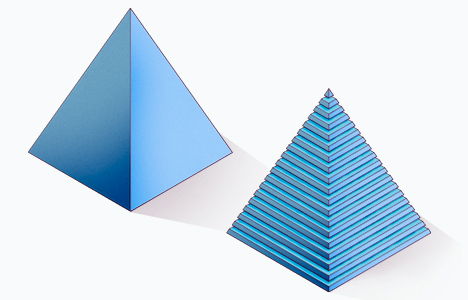

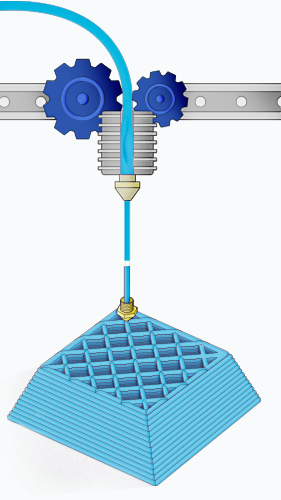

What is FFF technology?

What is IDEX technology?

Download White Paper “IDEX Technology: Doubling Productivity While Halving Costs”

The BCN3D printers are equipped with a unique double extrusion architecture: the independent double extrusion system (IDEX), the only extrusion system capable of printing with two heads independently.

Reliable dual extrusion 3D printing with IDEX technology

Because of the manufacturing strategy, sometimes it is required to build auxiliary support structures for those models with overhangs shallower than 45° from the horizontal plane.

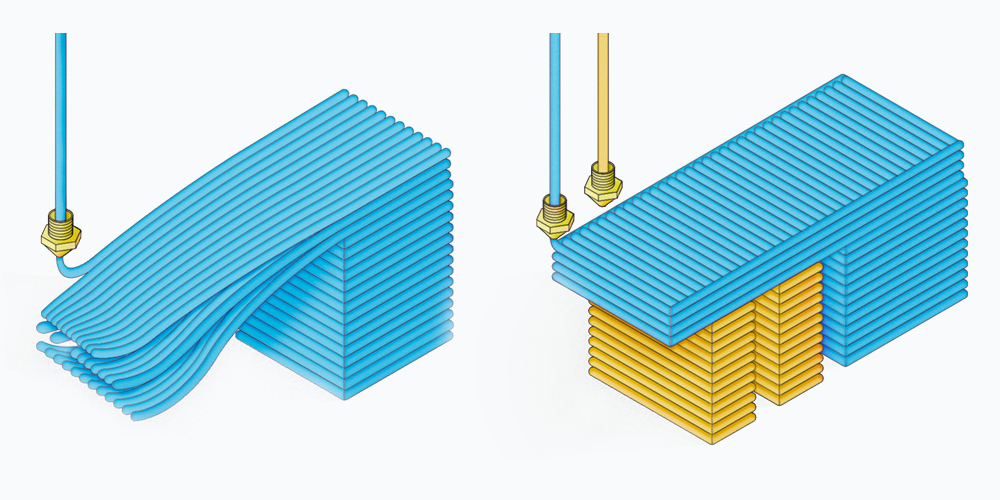

In the case of printers that only have one extruder instead of a dual extruder system, once the model is printed, it is necessary to perform a manual and time-consuming operation to remove the supports. This process affects the quality surface between the model and the supports and also increases the chances of breaking the part. In addition, depending on the geometry of the model it can be impossible to totally remove the supports by hand.

However, BCN3D proposition uses IDEX architecture to counteract the described disadvantage. IDEX architecture is the most reliable and neat solution on the market when it comes to dual extrusion technology. This is because the two extruders work independently when printing water-soluble supports or multi-material parts. While one extruder is printing the second one is parked, preventing the drip of molten plastic into the part. Conventional dual extrusion printers have both extruders together, which may result in filament threads left on the piece.

IDEX technology: Same investment, double productivity

IDEX is the only extrusion system capable of printing with two heads independently. This system allows enabling Duplication and Mirror printing modes capable of printing two pieces at a time. Double printing capacity means double productivity, all with the same investment. Unlike any other dual extrusion machines on the market, when you acquire a BCN3D machine, you get one printer but you double your productivity. All thanks to the IDEX technology.