Webinar

Use support materials to expand your 3D printing horizons

Our hosts and 3D printing specialists Álvaro and Jess give us the lowdown on all the different benefits that arise from using support materials, and all the different ways in which they can be implemented.

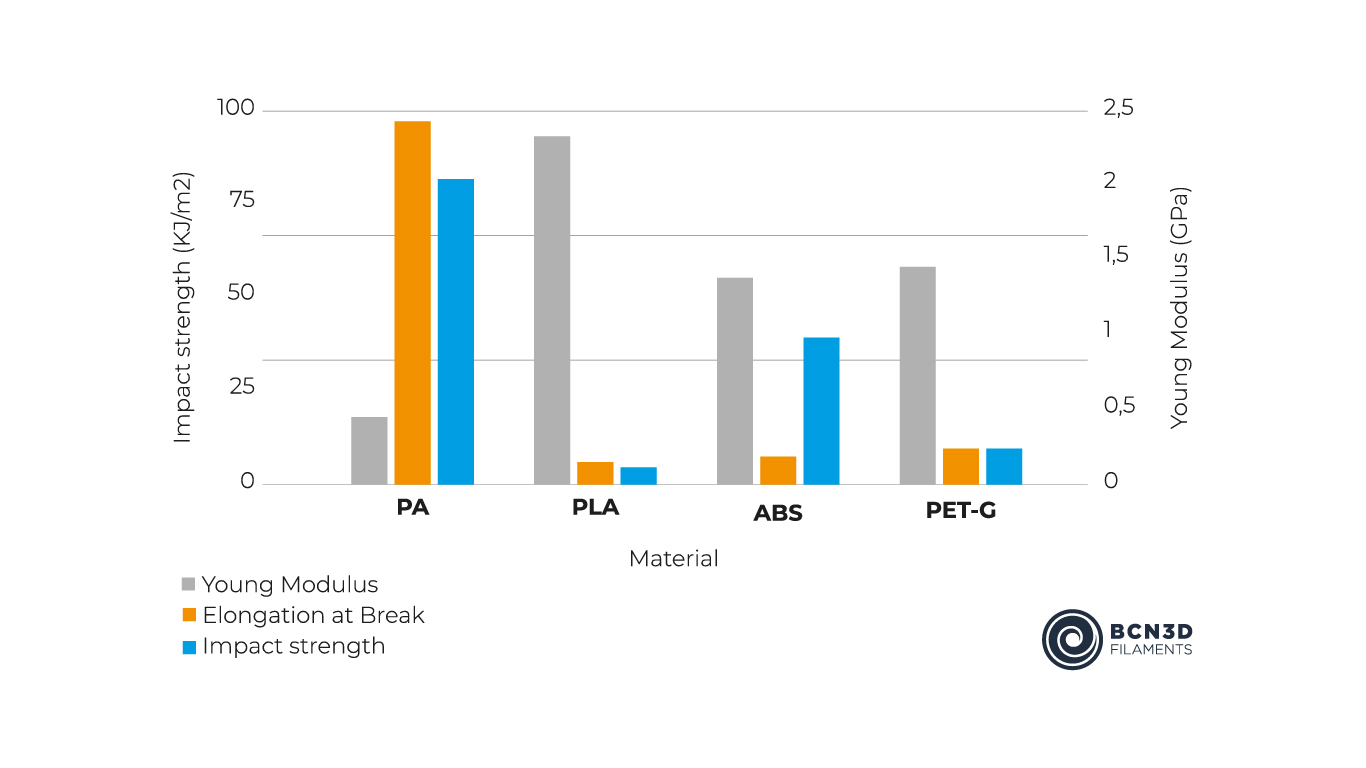

White paper

Your Extensive Guide to the Properties of 3D Printing FFF Filaments

This white paper dives deep into physico-mechanical properties and impact, heat and water resistances, by evaluating the performance of every material in the BCN3D portfolio.

Webinar

Materials for 3D printing & In-depth on fibre-filled

Which is the strongest 3D printing material? And… is stronger always better? In this webinar, Materials Engineer Dario Destro will walk you through the different 3D printing filament types currently available in the market and their properties, with a special emphasis on fiber-filled materials.

Success stories

NGNY Devices: Thousands in savings on end-use parts thanks to 3D printing

Incorporating in-house 3D printing at the engineering and fabrication workflows of end-use parts for their automated machines is saving NGNY over 40,000€ a year, while significantly accelerating their processes and facilitating customization from beginning to end.