NGNY Devices saves thousands by 3D printing end-use parts

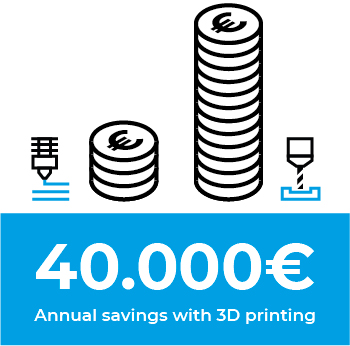

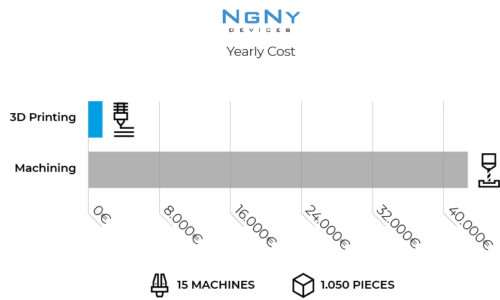

Incorporating in-house 3D printing for the engineering and fabrication of end-use parts for its automated machines is saving NGNY over 40,000€ a year. The process is significantly accelerating its workflow from start to finish, and facilitating customization.

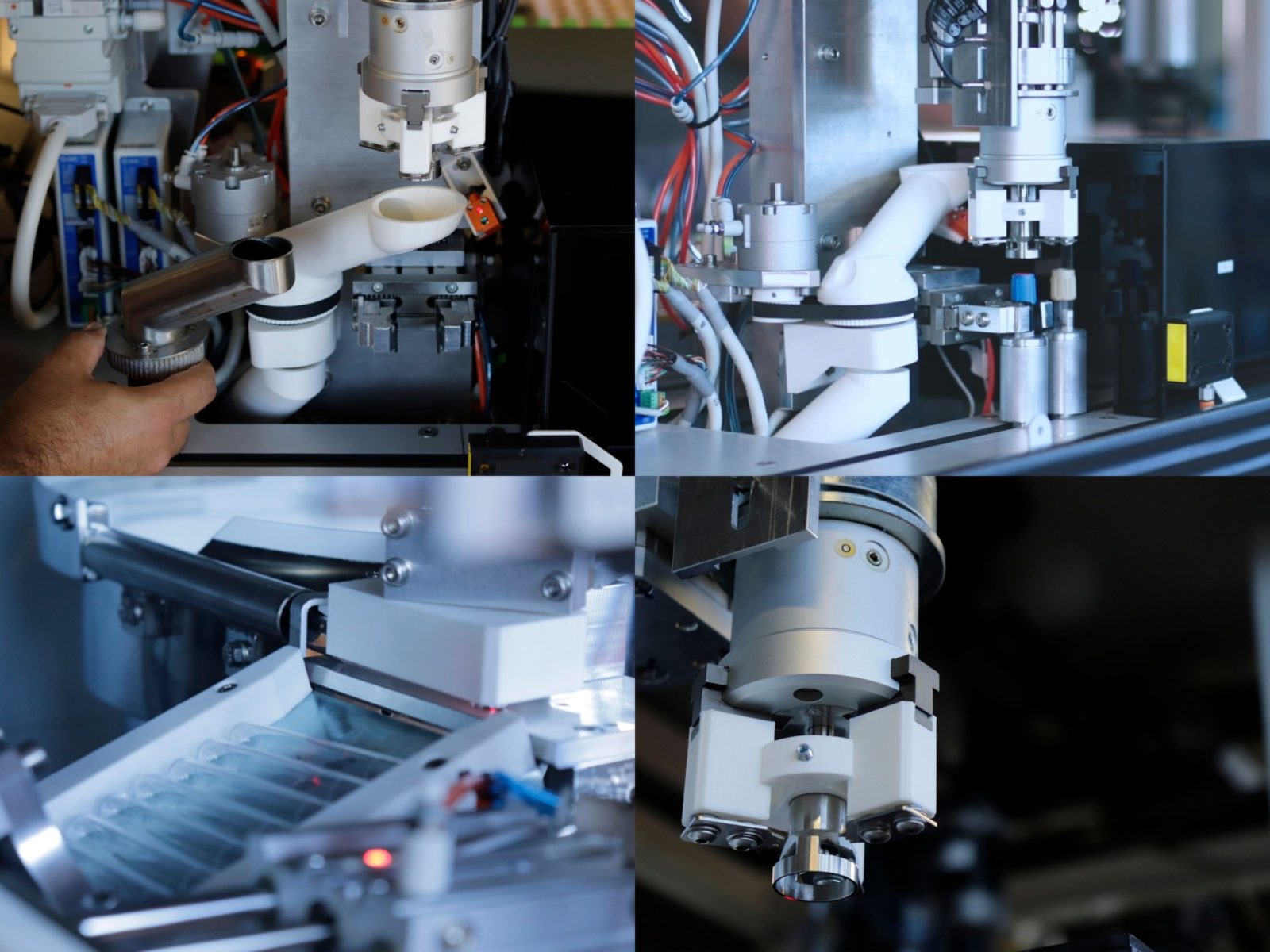

Founded in 2005, NGNY Devices works on the design and construction of machinery and automated equipment for repetitive processes. Its products are usually found in automated clinical laboratories, which are for testing blood and urine samples. These machines manage test tubes; they classify, uncover, make copies, retake, centrifuge, label and identify them. They can classify up to 1,000 tubes per hour, which, in the case of those 24 hour laboratories, equates to up to 24,000 tubes per day!

Each NGNY machine serves a different purpose, and has to be completely customized for the client. Therefore, the company is constantly working on conceiving new pieces which will enable new functions. In order to accelerate their design and fabrication processes, NGNY uses in-house 3D printing to develop, test and produce end-use pieces for each machine they construct.

In-house 3D printing yields savings of tens of thousands

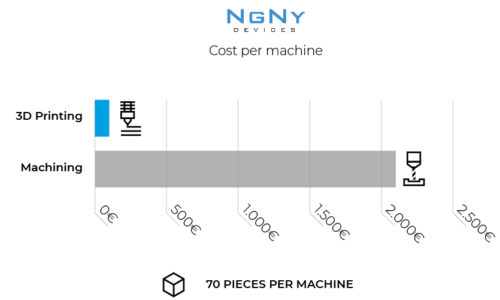

Before they started integrating additive manufacturing into their workflow, the staff at NGNY would design each new iteration and send it to an external supplier for machining. This was a slow and expensive process, with a minimum cost per piece of 30€.

Each design would then have to be tested and, if any changes needed to be made, a new piece would be machined, adding 30€ more to the total cost. Machining an average of 70 final pieces – not counting the different iterations created in the process – would yield a minimum cost of 2,100€ per machine, adding up to around 50,000€ a year.

According to Tomeu Ventayol, Project Manager at NGNY, 3D printing has completely revolutionized their process. Nowadays they 3D print “50 to 100 end-use pieces per machine, at a total cost of under 100€”. The math is simple: through 3D printing, over 2,000€ are saved up per machine – with a total savings amount of 40,000€ per year!

“Our case is almost a textbook example: high added value, low production, high complexity – 3D printing fits like a glove!”, asserts Tomeu Ventayol. “The first phase was changing our whole process, and the second has been to start designing parts for FFF and fabricating them, for which our BCN3D Sigmas have worked ideally”.

From functional validation to the fabrication of end-use parts

At NGNY, they develop the parts, 3D print them in PLA or PA depending on their intended use, and start testing them. They go through an iteration process, in which the product designers maintain the original specifications while adding slight modifications until they come up with a part that fulfills all mechanical requirements.

The final step of this operation is to implement the new parts in the specific machine that is being constructed. Once they have found the optimal design, they fabricate many of the final pieces using their Sigma 3D printers. They do so with complete confidence because, as Joan Viladomat, CEO of the company, states, “with 3D printing we obtain perfect results every time”.

NGNY has saved a colossal amount of time and costs in their reliable 3D printing process. 3D printing also allowed them to accelerate their time to market, which you can read more about here!

Find out how you, like many other designers and engineers around the world, could work smarter and innovate faster introducing BCN3D printers on your desktop or workbench – learn more about our products.