Webinar

The Ultimate ABS Guide

Join us as we dive into the world of ABS filament, a versatile and durable thermoplastic material widely used across the entire manufacturing industry. In this episode, we'll uncover the unique characteristics and capabilities that make it a top choice for you!

Webinar

Use support materials to expand your 3D printing horizons

Our hosts and 3D printing specialists Álvaro and Jess give us the lowdown on all the different benefits that arise from using support materials, and all the different ways in which they can be implemented.

Success stories

Hyperloop CHF’s train prototype with 3D printed parts goes for gold at the Hyperloop pod competition

We followed Hyperloop CHF’s journey of the creation of a high-speed subsonic train prototype to the 2021 Hyperloop Competition in Valencia. Using a BCN3D Epsilon W50, the team could quickly and efficiently 3D print molds and end-use parts in a variety of different materials.

Success stories

The BCN3D Epsilon W27 helps Agri.Builders’ Pherodrones fly high

As an alternative to pesticides, Agri.Builders has developed drone attachments to transport rings that release hormones to prevent damage to almond trees. The partnering of their BCN3D Epsilon W27 with their Smart Cabinet ensured a smooth-running of their printing process and presented them with an array of materials to choose from.

White paper

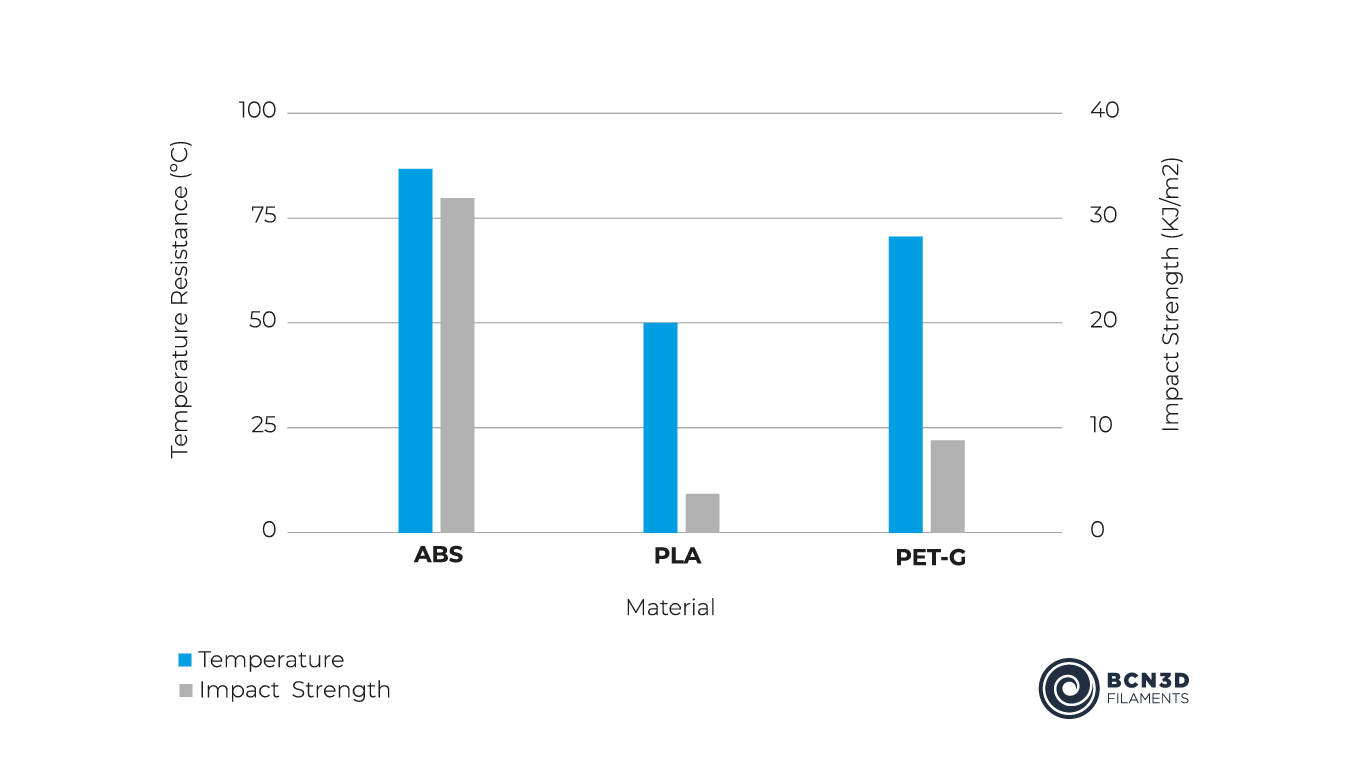

Your Extensive Guide to the Properties of 3D Printing FFF Filaments

This white paper dives deep into physico-mechanical properties and impact, heat and water resistances, by evaluating the performance of every material in the BCN3D portfolio.

Webinar

Materials for 3D printing & In-depth on fibre-filled

Which is the strongest 3D printing material? And… is stronger always better? In this webinar, Materials Engineer Dario Destro will walk you through the different 3D printing filament types currently available in the market and their properties, with a special emphasis on fiber-filled materials.

Success stories

KAV is Bringing Bespoke Helmets to the Masses

Every year there are 3.8 million concussions from athletic endeavors. However, the six on the hockey team of Whitman Kwok’s son are what compelled the creation of KAV. Foam-based helmets, the only option in hockey and most every other sport, provide limited protection against rotational accelerations while injection molding constrains helmets to a limited number of sizes compromising fit and safety. KAV’s mission is to elevate athletic performance and protection with highly engineered, bespoke helmets.