IDEX 3D Printer: Revolutionizing the Future of Printing

Thanks to the IDEX 3D printer, the days of losing time and budget to antiquated 3D printing technology are gone.

Yesterday’s single-extruder printers could generally handle basic additive manufacturing processes, but also came with significant limitations. When it came time to produce a component with an overhang shallower than 45 degrees from the horizontal plate or a piece containing multiple materials, hassles ensued.

Printing pieces with a shallow overhang often required the use of an auxiliary support structure during the printing process, which was inevitably difficult and time consuming to later remove. Plus some of the more complicated production jobs were entirely out of reach.

Today, BCN3D’s signature IDEX technology provides users not only with the full capabilities of a dual extrusion but also the option to use two independent extruders in the same machine. Here’s how the IDEX independent dual extrusion system is transforming 3D printing.

Technological Evolution

BCN3D’s first modular 3D printer, the BCN3D+, was initially developed in 2013 and dual extruders were added shortly thereafter in 2014. This dual extruder technology was pivotal to the evolution of 3D printing technology as it enabled printing with two different materials or two different colors. However, at this point there were still some remaining printing limitations on account of the dual extruders being over the same tool head.

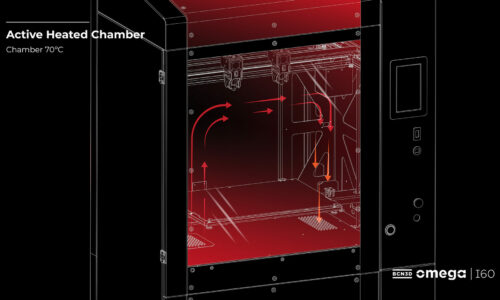

Fortunately, further innovation solved this dilemma: BCN3D’s pioneering IDEX technology has doubled the axes of a conventional 3D printer. In a standard printer, one series of mechanical axes (X, Y, Z) positions the tool head and product spatially, while another axis (E) manages the progress of the filament in the extruder. An IDEX printer, on the other hand, also adds X0, X1, Z, E0, and E1 axes.

These additional axes allow the printer to keep sharing the Y and Z axes – while each extruder has its own X and E axis – thereby making it possible to print with two independent tool heads. With this new design, one extruder can stay at rest while the other prints, preventing extraneous plastic threads from being dripped onto the product.

Superior Capabilities

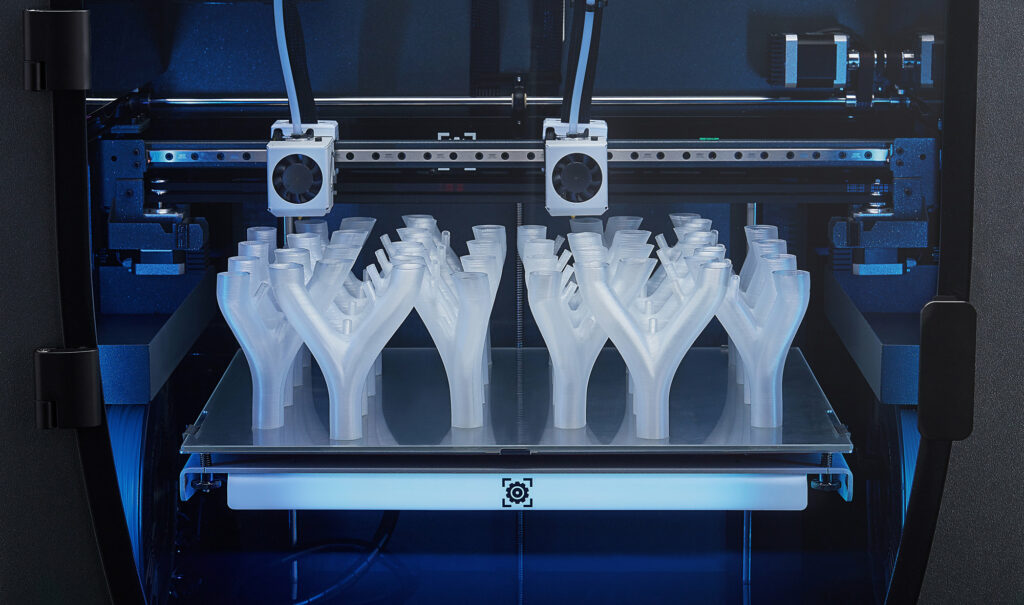

With Duplication and Mirror printing modes, the IDEX printer’s two independent extruders can print two pieces in tandem. Doubled print capacity means doubled productivity, as the same number of components can be printed in half the time it took with prior technology.

BCN3D’s IDEX technology also makes it possible to produce significantly more complex pieces. Different nozzle sizes can be combined to prepare intricate print jobs, and the dual extruders facilitate printing with two different materials or two different colors. With IDEX, hydrosoluble supports can also be used to create more complex structures without the hassle of later removing a traditional non-soluble support.

IDEX 3D printers are not only readily adaptable to diverse project requirements, they are also intuitive to use with only a short learning curve for operators. They can be shipped, received, and set up in a short timeframe, providing a quick turnaround time on the investment. Quality is guaranteed, as every printer undergoes a thorough quality check of both its mechanical and electronic systems and a test print before delivery.

Powerful Benefits of the IDEX 3D printer

BCN3D’s IDEX technology provides the fastest and most cost effective solution for 3D printing, optimizing time and productivity. By printing twice as many pieces in the same timeframe as traditional printers, costs can be cut in half. With IDEX printing businesses can benefit from:

- 50% lower machinery costs – half the number of printers can produce the same volume, delivering immediate cost savings on equipment

- Reduced overhead costs – less space is needed to house the printers, reducing their impact on recurring facility fees

- Decreased maintenance costs – fewer machines means less time and money spent on equipment setup, upgrades, and repairs

- Minimal training costs – IDEX printers don’t require investing additional resources toward specialized operators or complex training

What’s more, innovation can be maximized by combining materials to obtain novel mechanical properties and using soluble supports to produce more complex geometries. The feature of dual extruders on independent tool heads ensures both the highest quality and the greatest flexibility, providing an excellent ROI (return on investment) for the IDEX 3D printer.

IDEX 3D Printer: The Future of 3D Printing Has Arrived

IDEX technology is revolutionizing the 3D printing industry. Its advanced functionality empowers businesses to print the highest quality components in the least amount of time, while also pursuing limitless possibilities for innovation. Contact BCN3D today to learn more.