KAV is bringing bespoke helmets to the masses

KAV creates bespoke helmets to elevate athletic performance and protection, by using the IDEX technology in its BCN3D Sigma printer.

Hockey Places Extreme Requirements on Helmets

Ice hockey is a fast-paced game with over 1.5 million registered players worldwide and millions more who enjoy it recreationally. Players skate at 32 km/h, shoot the puck upwards of 130 km/h and constantly jockey for position on the ice, making it an exciting sport for spectators.

These feats of athleticism place significant demands on equipment. Helmets must not only protect players, but they must also be comfortable and fit well to be able to handle all the rapid movements of players. Existing helmet technology has relied on closed cell foams and injection molding for more than three decades and has fallen behind the increased speed and power of today’s game.

With the advent of 3D printing, new opportunities for performance, safety, and personalization have presented themselves. BCN3D is a critical partner in KAV’s 3D printing processes.

Protection, comfort, and fit

KAV’s main goal is to solve the problems of helmets that go hand-in-hand: creating a good, comfortable fit that also ensures safety. To achieve this, KAV decided to center 3D printing at the core of their design and manufacturing workflow. KAV wants to create the best experience for its customers by focusing on the following characteristics:

- Design from the ground up to reduce rotational and linear accelerations.

- Personalized fit, to accommodate not only many head sizes but also head shapes.

- Lighter weight, to minimize fatigue and encourage heads-up play and situational awareness.

- Extensive ventilation and non-insulating materials, for unmatched thermal regulation which also minimizes fatigue.

- Completely integrated fasteners, to eliminate bolts that rust, break or occupy critical space in potential zones of impact.

In summation, with 3D printing, the KAV Hockey Helmet is able to ensure the functionality of the three most important aspects of a hockey helmet: protection, comfort, and fit.

The importance of BCN3D printers in design and production stages

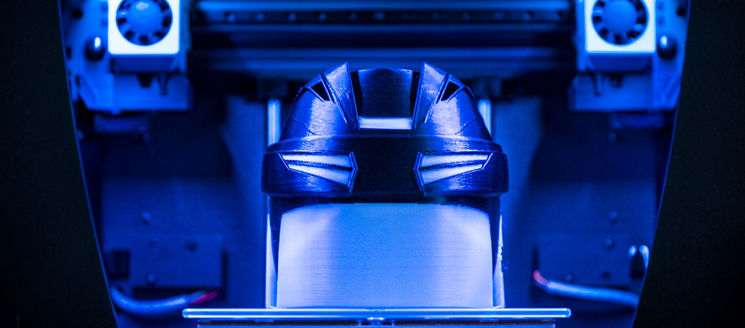

KAV uses 3D printers as part of their design workflow and has also fully integrated them into its manufacturing process. Designs are printed, reviewed by athletes, and tested for impact resistance in a matter of days. The company takes into account user feedback and optimizes helmets to minimize impact forces associated with head trauma.

KAV chose the BCN3D Sigmax printer for its IDEX technology, which ensures a clean transition between materials when using water-soluble supports, and for its massive printing volume to accommodate the large fixtures needed for KAV’s fabrication plant. Additionally, the mirror and duplication modes allowed KAV to maximize their productivity, by printing helmet accessories in half the time.

Next generation performance thanks to 3D printing technology

Manufacturing helmets via injection molding requires significant tooling and large batch runs. This makes it impractical for creating a variety of sizes to accommodate the unique dimensions of each athlete’s measurements. Furthermore, the design restrictions dictated by manufacturing molds limit the performance potential of helmets. Outsourcing the production of the printed parts would have cost KAV at least 4x more, and increased lead times by a week.

3D printing is the ideal tool to create tailored helmets, as it reduces the expense of tooling and opens up the use of novel structures. This is what has enabled KAV to produce a safer, better-performance helmet. The competitive price of the BCN3D Sigmax printer made in-house prototyping and production a reality.

KAV is using the unique strengths of 3D printing to offer the best performance of their products, through personalization to their ice hockey helmets.

Would you like to know more about 3D printing? Request a personalized demo of BCN3D printers that will help you visualize all the possibilities and capabilities.