An in-depth look at a 3D printer with auto leveling and autocalibration

Your BCN3D 3D printer with auto leveling and autocalibration takes away the need for a time-consuming manual process at the beginning of your print job. With the use of a piezoelectric sensor, you can always rely on the perfect first layer adhesion. Our XY alignment also ensures immaculate printing in dual mode with IDEX technology.

Calibration has a name for itself as one of the trickiest steps in the procedure of obtaining the best functioning in systems of all kinds of equipment – this is where your BCN3D 3D printer with auto leveling and autocalibration comes in! The automation of this process means a transformation in the way we set up our printers and the results we achieve in our printed parts.

What makes the autocalibration in our BCN3D printers unique is the XY alignment process, a specific function for our Independent Dual Extrusion technology (IDEX). While other forms of this technology require several different sensors to achieve full autocalibration, ours is performed with just one… Let’s take an in-depth look at how each step in the autocalibration procedure works.

Your 3D printer with auto leveling: Mesh mapping edition

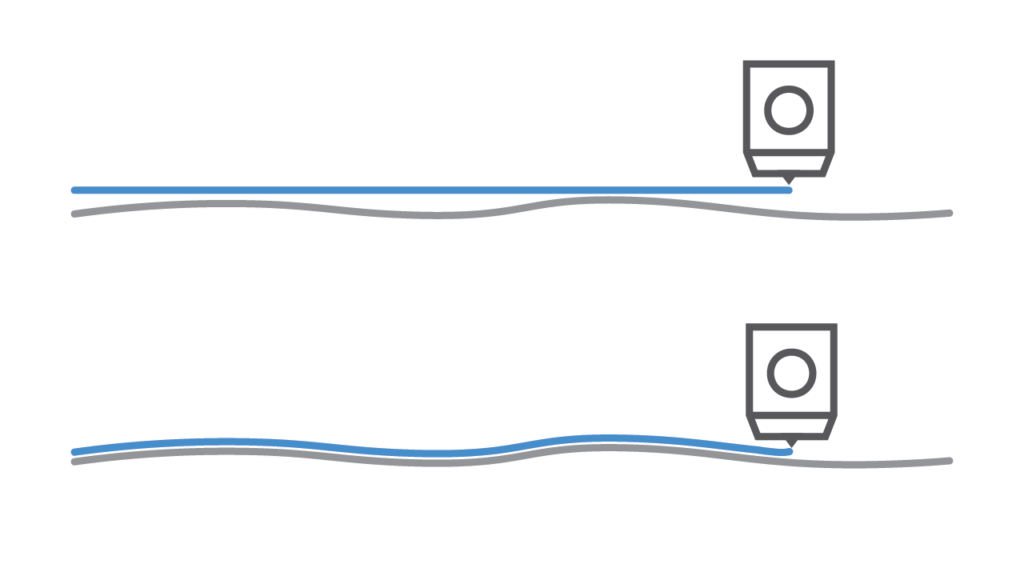

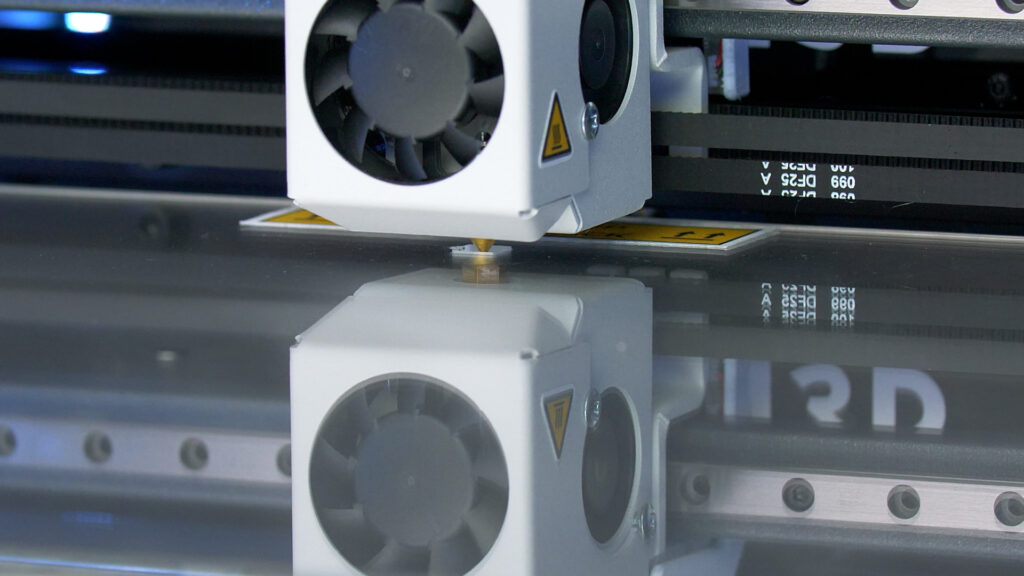

First things first, auto leveling is made possible by a piezoelectric sensor. The extruder board in control of the electronics system is connected to this sensor which is mounted on the printhead between the hotend and the x-axis. Its purpose is to detect pressure using the electric charge that arises when mechanical stress is applied in order to accurately measure the required distance between the tip of the nozzle and the printing surface.

Mesh mapping is one of the many wondrous advantages of this sensor and significantly improves the first layer adhesion. To begin is very simple – make sure you always correctly install, level, and center your printing surface in the same orientation, with the calibration square at the rear. With a clean nozzle, your printing head will probe using the tip of the nozzle to then measure the printing height surface in 9 points distributed across the build plate and map the height differences. It then compensates the build plate undulations with the Z-axis movements during the print. The required adjustments will be automatically activated and applied so that your printer is auto leveled for the most accurate alignment.

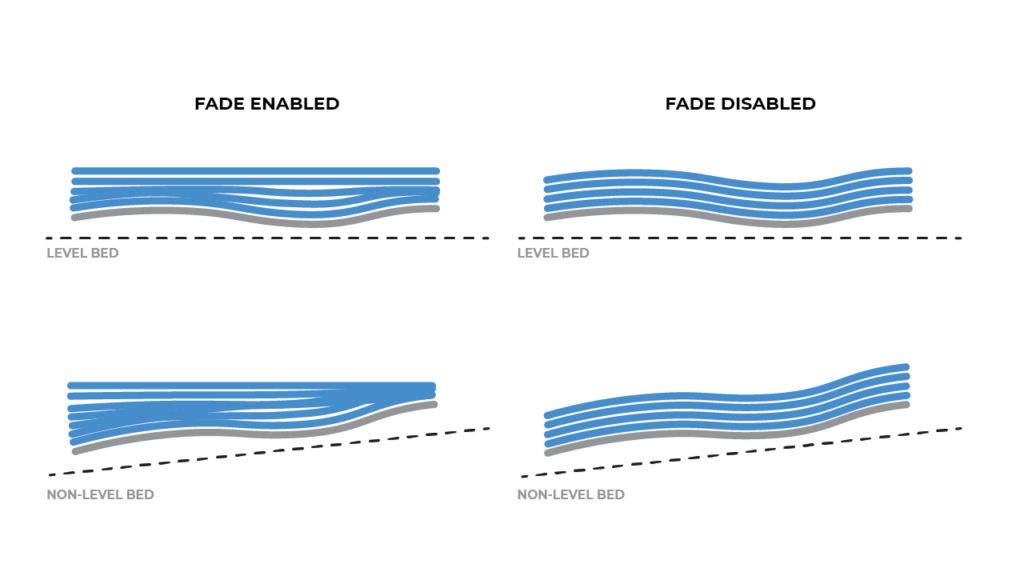

Integrated within all of our printers, you can also find a fade option. This comes in handy when you have a piece with ripples, as it allows you to compensate for these inconsistencies by adding more layers so that the following ones are progressively flatter.

Why XY alignment makes our autocalibration so special

Since our printers are equipped with our Independent Dual Extrusion System (IDEX), autocalibration also takes into account the XY alignment of the two toolheads. This is done through the use of a square located at the back of the printing surface. The toolheads use this small opening to touch the sides with the hotends, calculate their positioning on both the left and right axes, and subsequently calibrate the right offsets between them. This XY alignment ensures they are perfectly aligned and avoids any crossovers or shifting layers when printing in dual mode.

What all this can do for you

By solely ensuring your nozzles are clean, there’s no need for any extra work from your side. These automatic processes collectively mean you can reduce your printing set-up time from 40 minutes to just 6 – in other terms, a whopping reduction of 85%. By taking away the research and knowledge required for manual operation and a checking process, this foolproof technology means you are no longer dependent on human criteria. This reduces room for error or print failure and guarantees precision and a correct first layer adhesion every time.

Now it’s time to sit back, relax and let autocalibration do all the work for you!