BCN3D Technologies unveils new industrial-grade materials portfolio

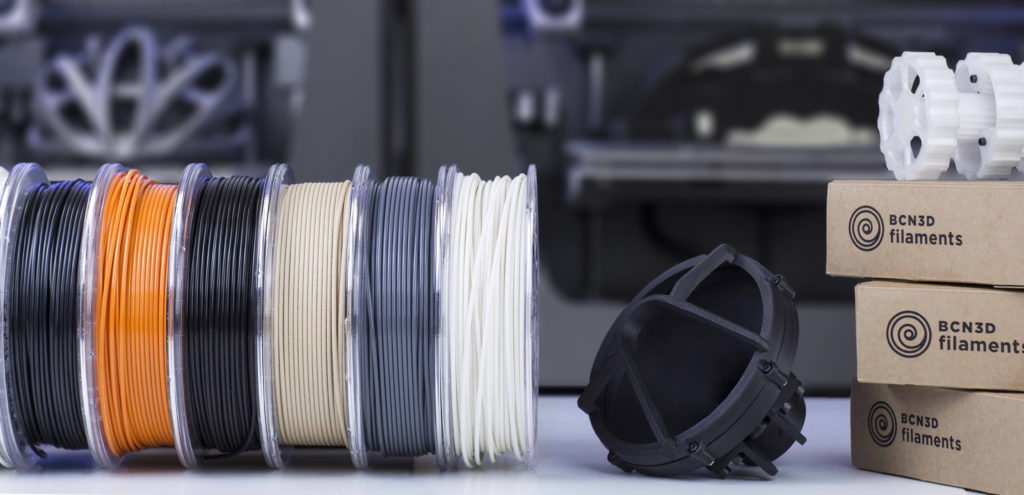

Barcelona, October 31, 2017 – Engineering applications have always been one of the most relevant interests among BCN3D users. Following the aim of enhancing the versatility of 3D printing and offering more dedicated solutions to the industry, BCN3D has developed a portfolio of technical materials under the label “BCN3D Filaments”.

These filaments are common polymers in several industries and cover the majority of the technical applications. The new portfolio released by BCN3D Technologies has been designed to deliver outstanding results for the Sigma and the Sigmax 3D printers, which include: PLA, ABS, Nylon, PET-G, a new reformulated PVA, TPU, and Composites. From now on, BCN3D Technologies will be adding more technical materials in order to provide the industry with the necessary materials.

- New reformulated PVA: With the goal of ensuring an even more reliable dual extrusion 3D printing experience, we have been working on a completely new reformulated PVA. This new formula works seamlessly with PLA, TPU, PET-G, and Nylon, becoming a reliable universal support material to print complex geometries, large overhangs, or intricate cavities.

- Nylon: Extensively used material for its unique mechanical and chemical properties. Thanks to characteristics like durability, flexibility, and resistance to corrosion, Nylon is ideal for multiple applications in the 3D printing field, like end-use parts or custom jigs and fixtures.

- PET-G: A globally used co-polyester, from plastic water bottles to cloth fibers, being 100% recyclable. As a technical material, PET-G provides better mechanical, chemical, and thermal properties than PLA with the same ease of use.

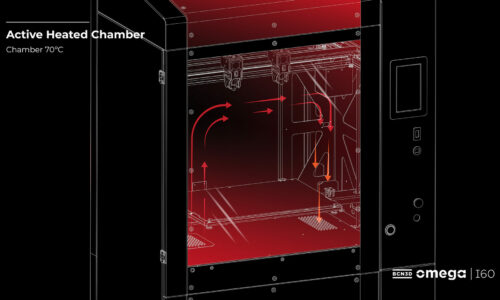

- ABS: Is one of the most common technical materials in several industries around the globe. Its great mechanical and thermal behavior makes ABS the ideal polymer for countless applications. Traditionally it has been a challenging material to print with FFF printers, however, the new re-formulated ABS ensures a good interlayer adhesion and warping reduction.

- TPU: Is a versatile rubber-like flexible material. With a Shore-A hardness of 95, TPU is a resistant material for several industrial applications, both mechanical and chemical. Moreover, it’s been specially designed to improve the 3D printing experience.

- PLA: Is a biodegradable, sustainable, and food-safe polymer made from organic sources. It is the most commonly used filament in FFF 3D printers for its ease of use and wide range of applications, especially those not mechanically or thermally demanding. Definitely a good starting point to learn about 3D Printing and manufacturing processes.

- Composites: Composites are materials with a polymeric base infused with other particles or fibers in different proportions. From wood to metal particles to achieve an aesthetic and attractive finish to carbon fibers to combine lightness and mechanical performance, composite materials for FFF printers unleash your creativity. Composite materials are not under the BCN3D Filaments brand and will be provided by Colorfabb.

Learn about which are the most common applications of each material, which are their properties, and how to print with them on our new materials website: Click here

BCN3D Filaments are the recommended materials for our 3D Printers, however, as an open filament system, our products are compatible with third-party materials for those users who are enthusiasts of other filament brands.

Order the new filaments portfolio in our web store: Click here

Are you interested to find out what BCN3D Technologies and our filaments can do for your business? Contact us at info@bcn3dtechnologies.com.