BCN3D Recap 2023: The most important highlights from the year

As we say goodbye to another remarkable year, the ending of 2023 marks an important moment for BCN3D. Rather than letting the achievements and innovations of the past months fade into memory, now is the perfect time to highlight the remarkable milestones we’ve made in the additive manufacturing industry. Join us as we take a retrospective journey through the significant milestones, breakthroughs, and accomplishments that defined our presence and impact throughout this year.

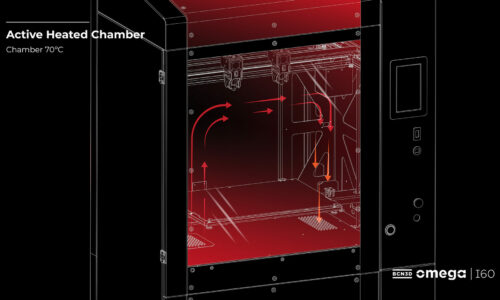

Introducing the BCN3D Omega I60: An industrial FFF 3D printer built for the factory floor

In June 2023, we proudly introduced the BCN3D Omega I60, an industrial FFF 3D printer meticulously crafted for optimal performance on the factory floor. Engineered to excel in producing large-scale, robust tooling, jigs, and fixtures, the BCN3D Omega I60 boasts cutting-edge features, including BCN3D’s renowned Independent Dual Extrusion (IDEX) technology. With an expansive print volume of 60L, a heated chamber reaching 70ºC, and a precision-controlled material operations system, this printer sets a new standard for industrial 3D printing. The direct-drive high-speed extruder further enhances its capabilities.

Over the past few weeks, BCN3D, in collaboration with their sales partners, has showcased their latest product, the BCN3D Omega I60, at various trade shows. These include Formnext in Frankfurt with iGo3D partner, Advanced Manufacturing in Barcelona and also in Madrid with their Spanish partner, Sicnova; 3D Print Paris with BCN3D’s sales partner in France, Imprimante3D; and Envitech in Brno with their partner, 3D Wiser.

Unveiling the New Generation of the Epsilon Series

The Epsilon Series proved itself to be the flagship of BCN3D since it arrived on the market in 2020. In January 2023, we introduced the New Generation of the Epsilon Series, which has been fine-tuned with new aesthetics, upgraded electronics, XYZ autocalibration, local network access and much more!

Reducing production times and manufacturing costs at RMC Motorsport

In April, RMC Motorsport, a rally sector leader, harnessed 3D printing to revolutionize internal processes for their N5 category rally cars. Founded by Roberto Méndez, the company sought to increase design capacity and streamline manufacturing. Choosing the BCN3D Epsilon W27 with IDEX technology, they transitioned from prototyping to producing end-use parts. This shift, including air intakes and bulkheads, led to a 40% cost reduction and a remarkable 5-hour turnaround for complex components. Notably, the technology allowed them to create intricate parts, like the air intake for the car’s filter, previously challenging with traditional methods. 3D printing has not only met but exceeded RMC Motorsport’s goals, offering freedom and innovation in their N5 car production.

Revolutionizing ABLE Human Motion’s exoskeletons design workflow, by improving rapid functional validation and prototyping with 3D printing

Last November, ABLE Human Motion, a pioneering medical device start-up in Barcelona, reshaped their exoskeleton design workflow through the transformative integration of 3D printing technology. Central to their mission is the active involvement of end users in the design process, enabling rapid iterations by incorporating valuable patient feedback. Prior to 3D printing adoption, testing proposals consumed a minimum of two weeks when using traditional manufacturing. Now, within a day, at a more affordable cost, 3D printing facilitates agile adjustments, speeding up the resolution of design flaws. This change has not only significantly decreased development costs and time but has also empowered ABLE to affordably prototype solutions, validate design improvements, and iterate production tooling in-house, without depending on external suppliers. Beyond cost efficiency, 3D printing enables the creation of more complex geometries, quick testing of new designs, and versatile problem solving, ultimately embodying a commitment to innovation, efficiency, and improved mobility for all.

To sum up, the above list highlights some of our most significant accomplishments during 2023. The unveiling of the new Epsilon Series, a flagship since 2020, showcased a redefined version boasting enhanced features like XYZ autocalibration and local network access. June saw the introduction of the BCN3D Omega I60, an industrial FFF 3D printer setting a new standard with its Independent Dual Extrusion (IDEX) technology, 60L print volume, and heated chamber. In April, RMC Motorsport harnessed the BCN3D Epsilon W27 to revolutionize rally car manufacturing, achieving a 40% cost reduction. November witnessed ABLE Human Motion’s revolutionary integration of 3D printing, streamlining exoskeleton design with rapid iterations and cost-effective solutions. These accomplishments highlight BCN3D’s commitment to innovation, efficiency, and showing the possibilities of additive manufacturing. As we embark on the new year, the journey continues towards unlocking our full potential.