An essential guide on fiber-filled materials for FFF 3D printing

This white paper will break down the properties and applications of fiber-filled materials, whose improved mechanical properties and higher thermal resistance make them ideal for engineering projects of all types.

Fillers have been used in the plastic industry since its beginning. The main purpose of fillers was initially to reduce the amount of costly polymer matrix in a blend, and so increase the economic yield of the manufacturing process. Fiber-filled materials present a number of benefits:

- Reduction of cost

- Improved mechanical properties (e.g. stiffness, hardness, impact resistance)

- Improved thermal resistance and thermal conductivity

- Reduce thermal expansion

- Fire retardancy

A special class of fillers is represented by fibers; contrary to spherical or irregular particles, fibers have a high aspect ratio. Tensile strength and modulus are properties that are normally enhanced by the addition of a fiber filler, such as glass fiber (cheap and stiff), carbon fiber (strong and heat resistant), aramid fiber (impact and heat resistant), and acrylic (cheap and low density).

Polyamides, such as PA, are commonly blended with carbon fibers; the two materials are exceptionally compatible, and in the right proportion result in a very stiff and sturdy blend. Carbon fiber-filled polyamides can be found in the automotive industry, for parts in contact with oils and subject to loads in aggressive environments.

Putting fiber-filled materials to the test

To better show the effect of the addition of carbon fibers to a polyamide matrix, we compared the properties of our two filaments PA (polyamide) and PAHT-CF15 (polyamide, 15% carbon fiber-filled).

PA is characterised as a flexible and durable material, ideal for moving parts, when sudden hits or falls are expected. The addition of 15% carbon fiber completely transforms the polyamide blend into a very stiff material, capable of withstanding heavy loads without flexing, even at high temperature.

An important advantage of the addition of fibers to thermoplastic is an improved thermal resistance, and subsequent better dimensional stability in hot environments, such as car engine bays, electric panels and in proximity of moving parts.

The addition of fibers in 3D printing filaments also affects the printability properties of the material. For example, in the molten state, the presence of rigid, solid particles greatly increases the melt viscosity of the blend, thus requiring higher printing temperatures to ensure an optimal flow.

Another aspect to take into consideration is the abrasive effect of solid particles/fibers. The use of carbon and (especially) glass fibers can result in a considerable wear of the classical brass nozzle over a relatively short period of time. For this reason, it is highly recommended to use a special hardened nozzle, such as the BCN3D Hotend X.

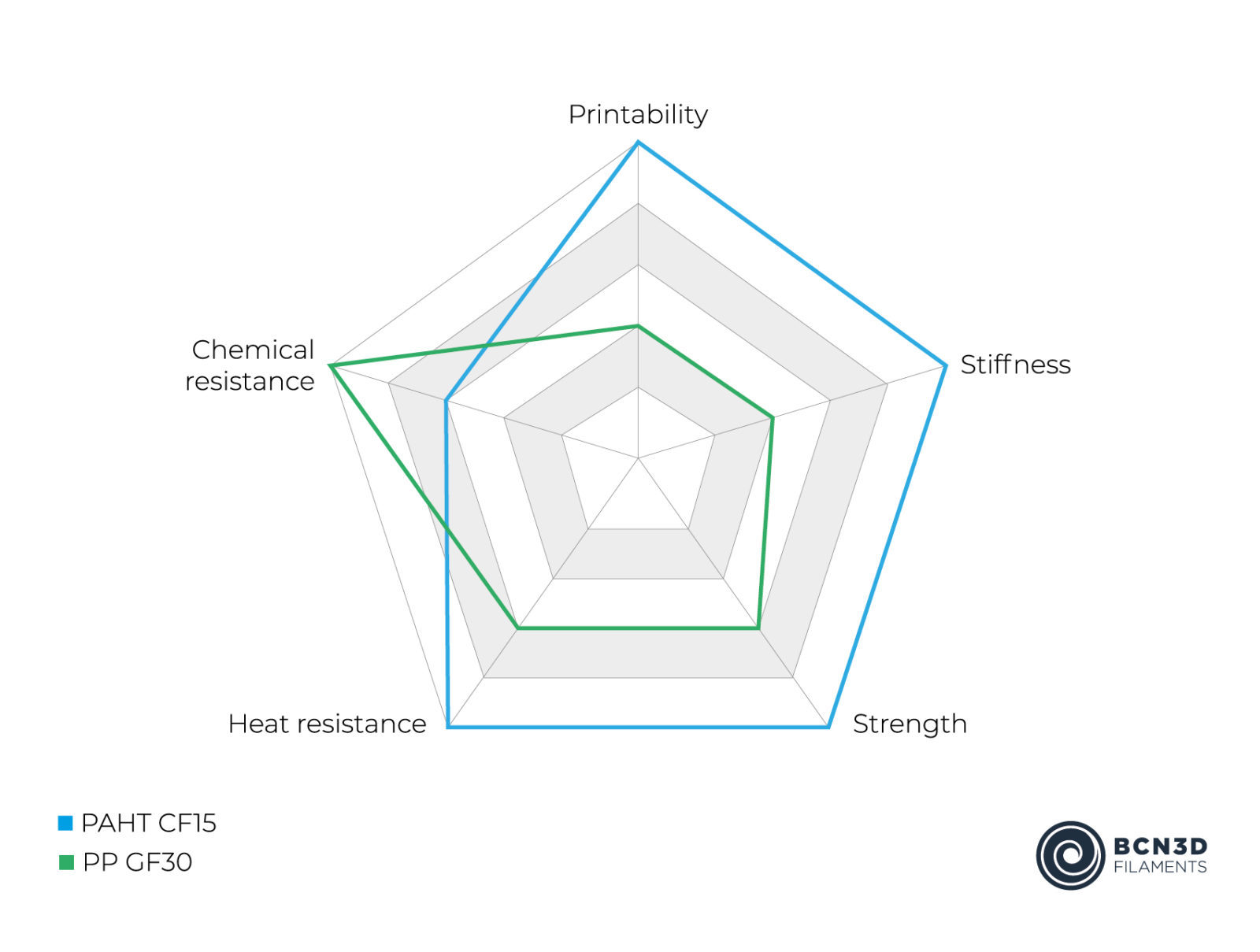

Our range includes PAHT-CF15 (polyamide, 15% carbon fiber-reinforced) and PP-GF30 (polypropylene, 30% glass fiber-reinforced). To find out all about them, have a read of our white paper!

Learn more

Would you like to know more about 3D printing? Check out the following white papers:

- Anatomy of Sigma & Sigmax R19 extrusion system: Partnering with e3D™ & Bondtech™ manufacturers

- Introduction to FFF technology and its most important parameters

- Introduction to Fused Filament Fabrication (FFF) 3D printing technology

- Guide on how to choose a professional desktop 3D printer – White Paper

- Introduction to the Plastic Manufacturing Industry – White Paper

Ready to save time and cut costs with a BCN3D printer? Request a customized quotation for a BCN3D Printer.