Odapt: Improving ostomates quality of life with 3D printing

Ostomy surgery as a life saving procedure

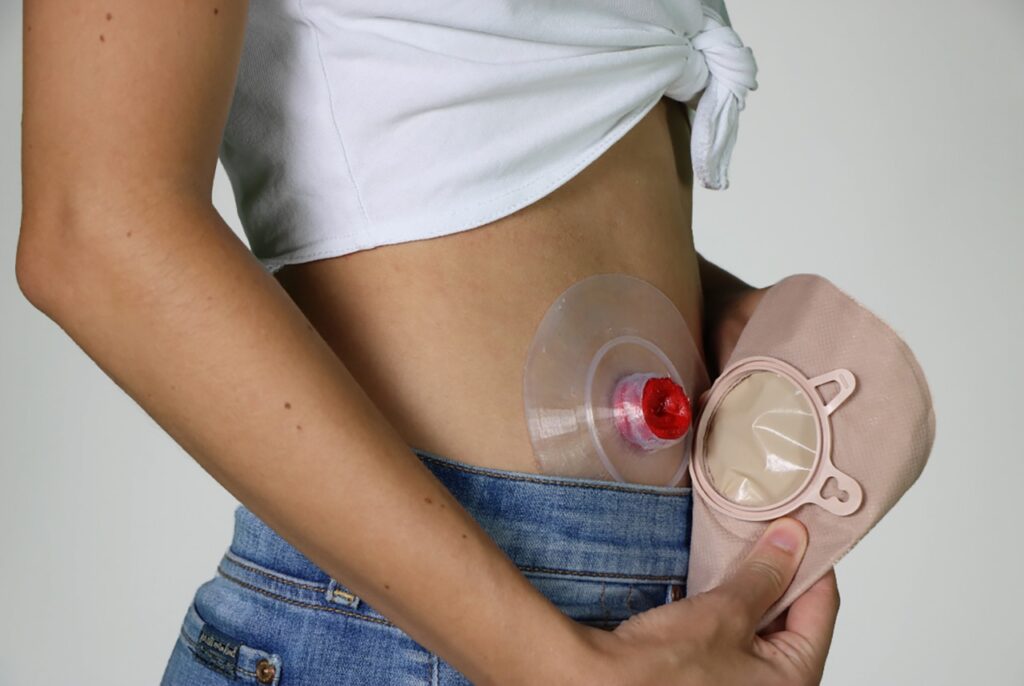

An ostomy is a surgical procedure in which a stoma (an opening) is created in the abdomen to allow waste to pass out of the body into a prosthetic known as ‘ostomy bag’ on the outside of the body. This can be required for various medical conditions such as bowel cancer, Crohn’s disease, ulcerative colitis, or other intestinal disorders and it can be temporary or permanent. The ostomy bag where the waste is collected is attached to the skin around the stoma.

More than 15 million people worldwide live with an ostomy bag. The design of the bags has merely changed since its invention despite having many problems which include leakage, lack of attractiveness, skin irritation, ballooning (gas) of the bag amongst others.

Leakage is the main problem associated with ostomy bags with 99% of ostomates having experienced a leak at least once and 50% experiencing them frequently (daily or weekly). This is a huge burden on ostomates’ quality of life. Leaks are mainly due to a lack of adaptability of the wafer to different types of stomas.

Odapt’s Ostomy Bag transformation with 3D printing

Odapt is the first 3D printed silicone wafer designed to avoid leaks. Thanks to 3D printing technology, the design of the wafer is adapted to any shape of stoma and to any pouch existing in the market and even to any color! By eliminating leaks, the problem of skin irritation is also reduced.

People change their wafers every 2-3 days, some do it even daily. This creates a huge quantity of medical, non-recyclable waste. With Odapt, this waste is eliminated, thanks to a re-usable wafer that can last for months, being easily cleaned with soap and water. This is possible thanks to the material used: biocompatible silicone with a biocompatible gel that works as an adhesive.

Currently, ostomates need to measure their stoma, cut the wafer manually and remove adhesive strips. This process can take around 20 minutes for experienced users and can be very overwhelming especially for the elderly. Odapt, allows ostomates a simpler way of using the wafer, as it is already cut to the perfect shape of the stoma and it doesn’t require manually removing strips.

About Odapt

Odapt is the result of the final Master’s project in Industrial Design Engineering of the students Jessica Nissen (Designer), Patricia López (Design & Industrial Engineer) and Ivana Llobet (Biomedical Engineer) at ELISAVA School of design in Barcelona. For two years, the team has been closely working with people living with ostomy bags (reached via patient associations and Instagram influencers), stoma therapists and surgeons (from St Mary’s Hospital in London, UManresa and Hospital Clínic of Barcelona). The team is receiving a lot of interest from users that reach out willing to contribute to the project. The new prototype is currently being tested with four volunteers in Barcelona.

Odapt has won 25 000€ as part of the BASF Forward AM Innovation Award, which allows the team to continue the project in collaboration with the Iam3DHub team of engineers. Odapt has also been nominated to the Elisava Master Awards 2023 as well as the James Dyson’s Award 2022. The project has been exhibited at Formnext 2022, the biggest 3D printing fair in Europe.