BCN3D Slicing Guide 4: Master infill settings

The 4th BCN3D slicing guide is here to help you master infill settings so you can obtain the perfect mechanical properties.

A great 3D printing experience requires more than just making great hardware. At BCN3D we’ve developed BCN3D Stratos, an advanced slicing software that allows you to make the best out of the BCN3D printer and material family.

If you struggle finding the right balance between part quality and print time, the infill settings are what you’re looking for. In this post, we’ll show you everything you need to know about infill and how to make the best out of it.

What is infill?

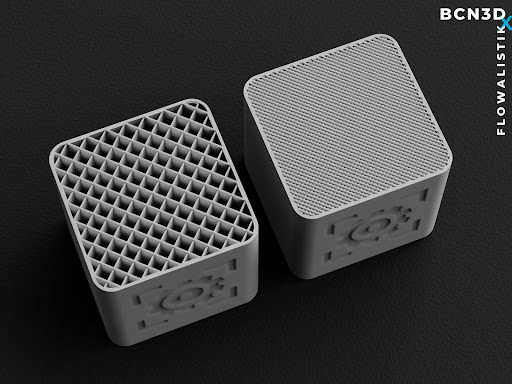

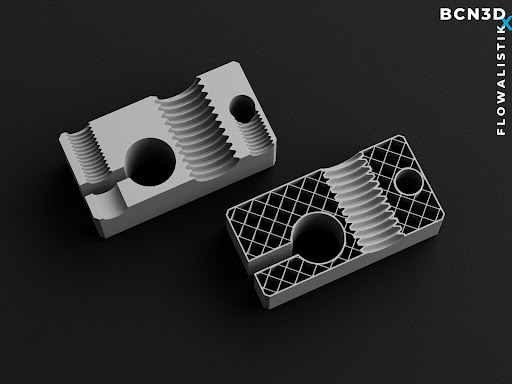

In the 3D printing industry, the infill refers to the internal structure that fills the inside of a 3D printed part. Components made with a 3D printer are rarely solid (100% infill). Instead, a low-density structure is 3D printed, saving manufacturing time and material while offering similar mechanical properties.

Invisible but extremely efficient

Infill is one of the manufacturing features that makes 3D printing unique. The infill settings allow you to decide the internal structure of the part, including its density and properties.

Traditional manufacturing techniques such as CNC, laser cutting, or injection molding force you to create either solid parts or to manually optimize the internal structure to make it lightweight. That involves additional prototyping and resources.

Essential infill settings

Even though you can find dozens of infill-related settings on BCN3D Stratos, two significantly affect the print quality: infill density and infill pattern.

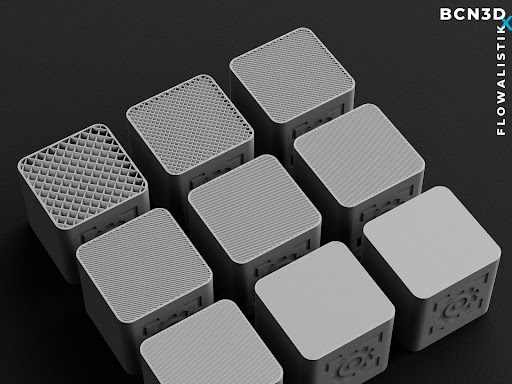

Infill density

This setting determines how solid the internal structure should be. It’s defined as a percentage, being 0% hollow and 100% solid.

For example, if a part is 3D printed with a 20% infill density, 20% of the inside will be filled with plastic, and the other 80% will be empty.

Recommended infill density settings

It’s essential to understand the part application to find the correct infill settings. Most initial prototypes are 3D printed with a low infill density, reducing print time and cost. However, final parts are usually made with a higher infill density to increase their strength.

- Aesthetic (5-10%): Used to make visual parts or early prototypes that don’t need to support any loads.

- Standard (10-20%): Most common infill density. It offers a reduced print time and part weight.

- Functional (20-30%): Recommended for functional parts that will be subjected to moderate loads.

- Advanced (30-50%): Used to make strong parts that require the best possible mechanical properties.

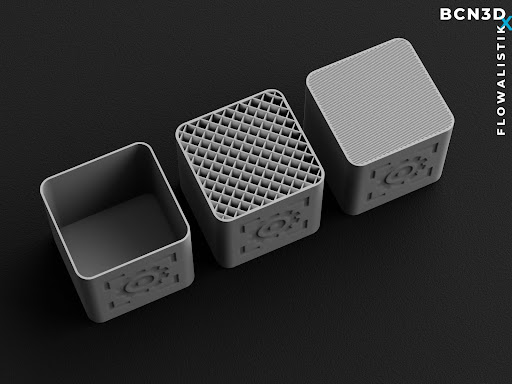

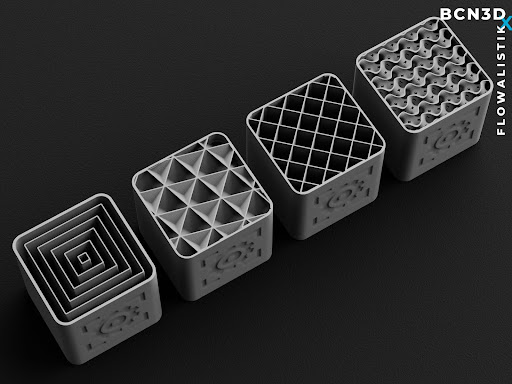

Infill pattern

The infill pattern refers to the shape of the structure inside of the printed part.

BCN3D Stratos offers more than ten types of infill pattern, ranging from simple lines to complex tridimensional shapes. Even though they all share a basic functionality, each one has unique features that make them appropriate for specific applications.

Recommended infill pattern settings

Each pattern is unique, and you should test all of them to find the one that works best for you.

- Line pattern: It prints simple lines that swap direction (90º) on alternate layers.

- Grid pattern: It’s one of the fastest infill options and it offers good mechanical properties.

- Gyroid pattern: This tridimensional shape distributes the strength and support in all directions.

- Concentric pattern: This type of infill pattern is recommended for parts that are 3D printed using flexible material.

How infill affects printed parts

Part weight

The higher the infill density is, the heavier the part will be. It’s as simple as that.

For example, the part you can see below weighs 67g when printed with a 10% infill. However, the weight increases to 126g when the infill changes to 40%. This means that a 30% increase in the infill density leads to an 88% weight increase.

Part strength

As it happens with part weight, the higher the infill density, the stronger the part.

If you’re looking for part strength, you may want to get started with grid, octet, or gyroid infill, although testing will always be required.

Internal supports

Even though infill is on the inside of the part and isn’t usually visible, it affects the outer layers of the model.

The infill also supports the top layers from the inside. If your part has a flat top part and the top thickness is too low, you may experience an issue called pillowing. This issue is usually caused by uneven cooling, although a low infill percentage will always make the problem more visible.

Taking these considerations, such as infill density, infill pattern and how the infill affects printed parts will ensure impeccable mechanical properties of your printed parts. Download our specialized white paper to find out more, or our all-in-one ebook featuring all 6 of our slicing guides below.