BCN3D Slicing Guide 5: Support material fundamentals

The 5th BCN3D slicing guide, in collaboration with Agustín Arroyo, provides you with the essentials of support material usage, its role within the 3D printing process, and some tips to improve your prints.

A great 3D printing experience requires more than just making great hardware. At BCN3D we’ve developed BCN3D Stratos, an advanced slicing software that allows you to make the best out of the BCN3D printer and material family.

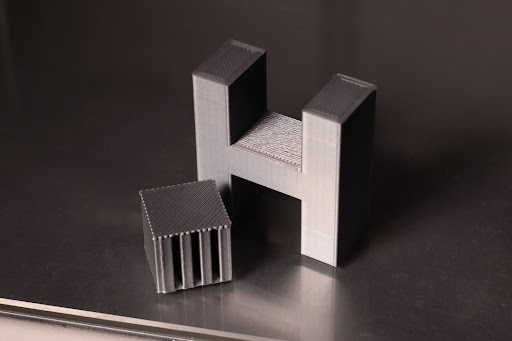

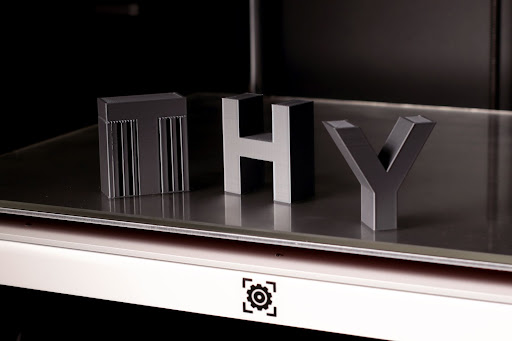

FDM 3D printing is an additive manufacturing process where objects are made by depositing material in a predefined way layer by layer. Each manufacturing process has different capabilities and limitations, and FDM 3D printing has one basic rule: Each new layer needs to be supported by the layer below.

But, what happens if your component includes overhangs or features that would be printed on air? Then you’d need to add a support structure.

The support material refers to the automatically generated structure that supports the overhangs and bridges of your model.

So when do you need support material?

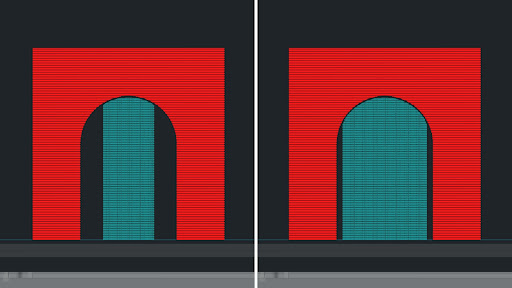

Overhangs

All overhangs that are over 45º from the vertical should be 3D printed using support structures.

Bridges

Bridges refer to those horizontal overhangs that connect two points with a straight line. Those under 10mm could be printed with relatively good quality without a support structure below.

Essential Support material settings

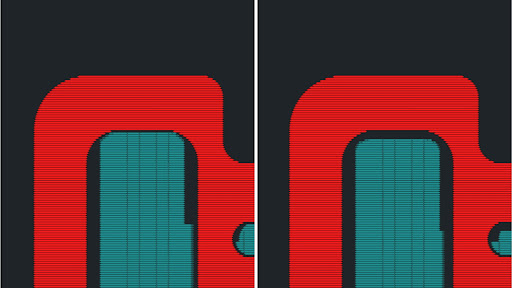

X/Y distance

If you need a clean surface finish on your design, consider increasing the X/Y distance to reduce the chances of getting the support structure stuck to one of the sides of your print.

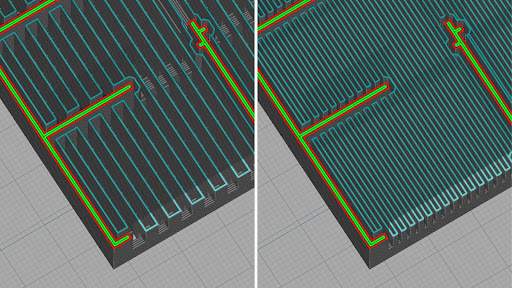

Z distance

This is probably the most critical support setting, and it sets the distance between the last layer of the support structure and the part it needs to support.

The standard Z distance is 0.2mm, although each design and material have unique values. It’s highly recommended to test this setting by 3D printing some samples before jumping to the final print.

Support density

The support structure is an automatically generated mesh. As it happens with the Infill, we can adjust the mesh density. The standard infill density is 15%.

Support overhang angle

If your model has overhangs at a different angle, you can choose which ones need support with this setting.

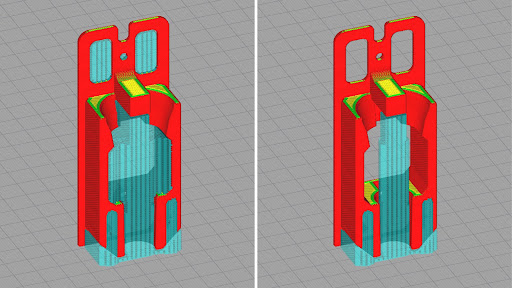

Support only on build plate

If you choose to place support structures everywhere, some of them may have their starting layer on top of the print, affecting the outer shell’s quality.

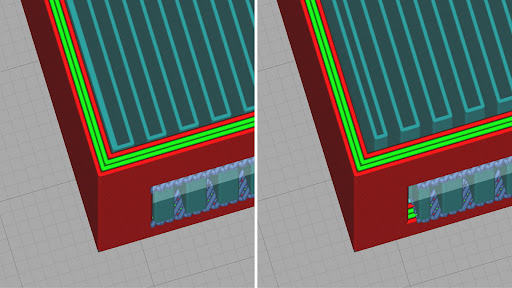

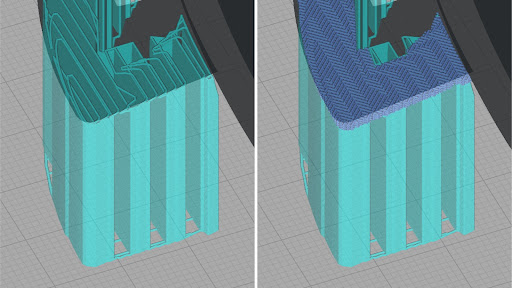

Support interface

This setting generates a dense interface between the model and the support. It’s a smooth surface at the top of the support structure on which the model is printed.

Removing supports structures with an interface is usually easier than removing regular supports, and the surface finish is generally better.

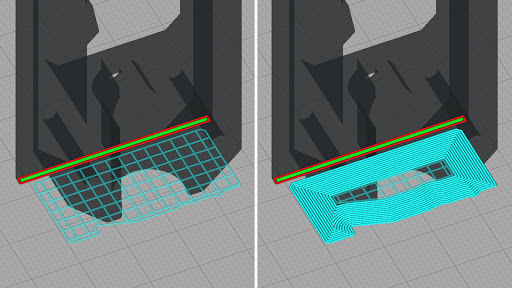

Support brim

This option generates a brim within the support infill regions of the first layer, increasing the support adhesion to the build plate.

Support materials

Thanks to the IDEX technology, you can use different materials in one print, offering new ways to manufacture quality components.

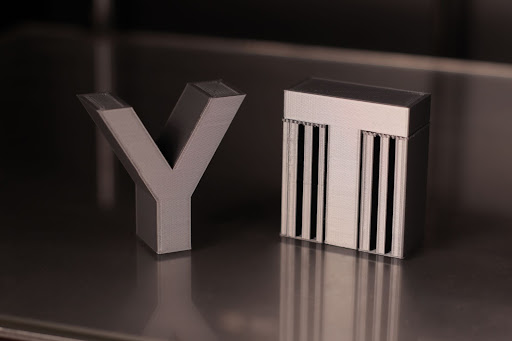

Same print material

If the print you’re manufacturing has a geometric design or doesn’t need to be accurate, you can use the same material for both the print and the support material.

- It is recommended for parts with simple or geometric shapes.

- Reduced print time compared to dual material prints.

- Increased part-support bonding as they’re the same material.

PVA

PVA is one of the most popular 3D printing materials. It’s exclusively used as support material because it’s water-soluble and can be easily combined with other popular materials.

- Water-soluble.

- It is recommended for complex parts that have internal cavities.

- Great adhesion with PLA, PETG, TPU, and Nylon.

Learn more about PVA with the How to print with BCN3D PVA and Tips and Tricks articles.

BVOH

BVOH (Butenediol vinyl alcohol copolymer) is a water-soluble thermoplastic optimized for the FFF manufacturing process.

- Water-soluble.

- Compatible with PLA, PETG, ABS, PA, and PAHT CF15.

- Fast to dissolve.

In summation, there are a number of settings and 3D printing materials to choose from to ensure your bridges and overhangs perform their intended purpose. To read about these considerations in more depth, download our specialized white paper or all-in-one ebook featuring all 6 of our slicing guides below.