Escofet 1886’s innovation brings new levels to landscape architecture

Escofet 1886 is a company with more than 130 years of history located in Barcelona, internationally recognized for its expertise in concrete and the development of urban elements for the city. We are pioneers in the integration of design in the industry, and innovators in the production of urban concrete furniture in public spaces, and our company is involved in the construction of the landscape architecture of our cities, to improve the people’s way of life and their environment.

Trying to always be at the forefront of technology, at Escofet we invest in the development of materials and their applications. In addition to the functionality, processes of manufacture and innovation of the product, we constantly consider the aesthetics, usability, sustainability and cost of each of our designs.

A few years ago, with the aim of furthering future relationships that design and technology will establish in the 4th industrial revolution, we incorporated 3D printing as another design tool, in order to work with greater efficiency and precision, save costs, reduce the development times of new products and accelerate their arrival to the market. It soon became an indispensable technique in the design validation process, to test surfaces modelled in the 3D software by defining details such as textures, part fits, tapers and the delivery of the blueprints.

A good example of this renewed process is the design of the drainage of the Satellite urban lounger, recently awarded a Silver Delta from ADI-FAD 2020. For this design to be validated by technicians and engineers, we needed to elucidate answers to some questions about the complexity of the shape of the channel; obviously to approve that it fulfilled its function of expelling water, but no less importantly to confirm the thicknesses of the pieces in this section. Also, where the planes met, that their angles and slopes were correct for a satisfactory demolding once the UHPC concrete had set.

The development of a new urban furniture design involves significant investments in models, molds and tooling. With the implementation of 3D printing technology, we can quickly create critical parts of a design for industrial validation and shorten product launch times, as well as reduce production costs. Another benefit is being able to print scaled models to verify its design or review the behavior of various components. For example, the spatial aggregation of different modules of the Highfive anti-intrusion security model, which aims to resist vehicle impacts and redirect traffic flows to ensure the safety of citizens. At the same time, it has been a very well-received tool for commercial purposes, as now we can physically show the client a customized piece from our catalog or even one made-to-measure, for a much better three-dimensional understanding.

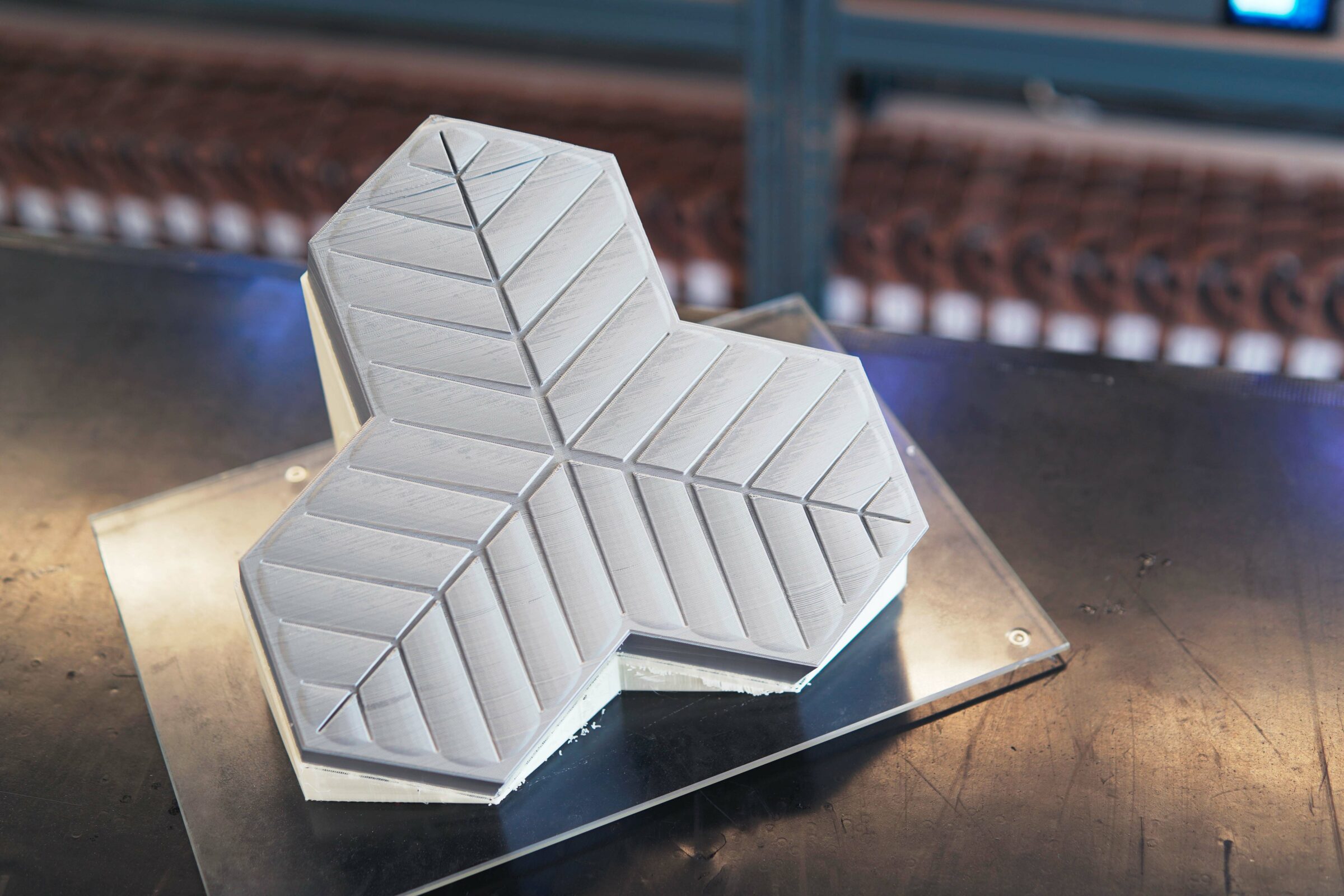

In the case of the Trébol tile, awarded with the Gold Delta of the ADI-FAD 2018, it was necessary to print several 1:1 scale models to analyze its texture and to verify that the connection between them was the one estimated by our Design Department. In the evolution of its design, we had to apply significant changes to its geometry since, due to a change in the production model, we had to invert part of the drawing to low relief, and therefore we needed to ensure that the thickness and angles of the ribs, as well as the curvature of the blade edges, were sufficient to achieve good production performance, excellent anti-slip conditions and a comfortable tread. Using 3D printing throughout this whole prototyping process meant very considerable time savings, which allowed us to move on to the next phase of product development much quicker.

At Escofet, we believe that additive manufacturing possesses an extraordinary potential for the industry and, to this day, it is still difficult to imagine which path it will take in the upcoming future, as the possibilities are so wide. We know that we can design new products and concepts with an unthinkable complexity, but we also strive to innovate in the ways of manufacturing. The prospects are promising and the ability to integrate technological improvements in the future production of urban furniture looks extremely hopeful.