3D printing at Escofet transforms city landscapes

Escofet transforms cities and public spaces through the design of elements such as lighting, pavements, and buildings. 3D printing is proving to be extremely useful for their iterative design process and has been vital for the creation of their latest piece, the Trébol tile.

For over a century, Barcelona-based Escofet has been an international reference in landscape architecture thanks to its expertise in concrete, used to drastically transform city landscapes.

With projects such as Palau Sant Jordi and the Olympic Ring under its belt, and collaborations with renowned architects as Enric Miralles and Benedetta Tagliabue, Escofet’s designs have been shaping Barcelona’s urban landscape since 1886, and have been honored with awards as prestigious as the Spanish National Design Award and the Golden Delta from the FAD Industrial Design Association.

The evolution of the company led it on a natural path to researching and working with new technologies and manufacturing practices, which allows it to take its vision even further. That’s why, in order to achieve new design possibilities, it started incorporating 3D printing into its processes for prototyping and functional validation.

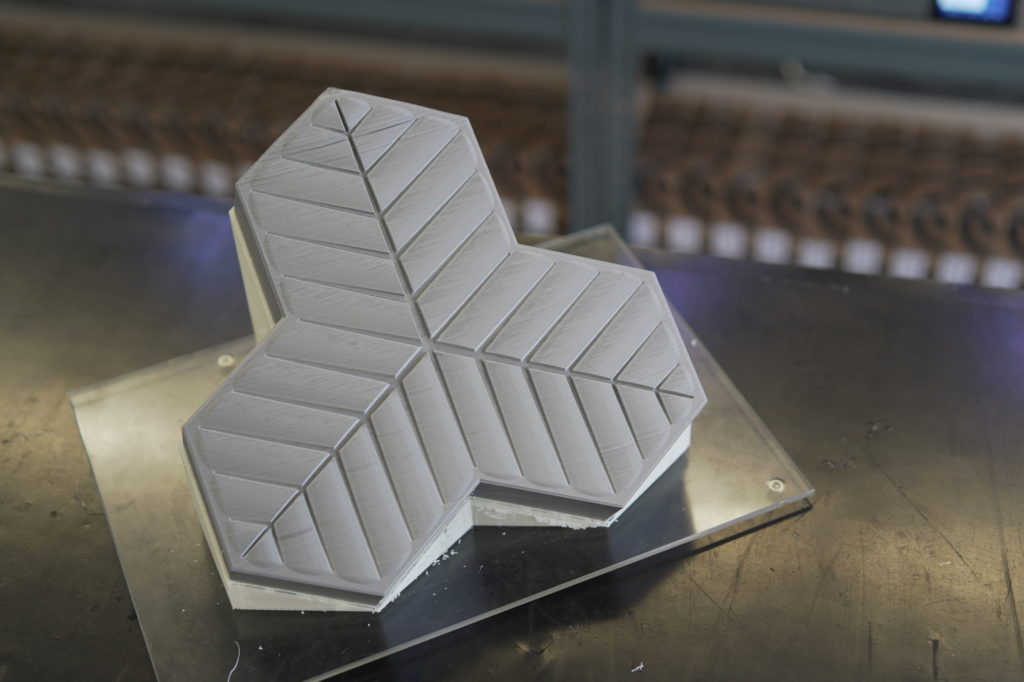

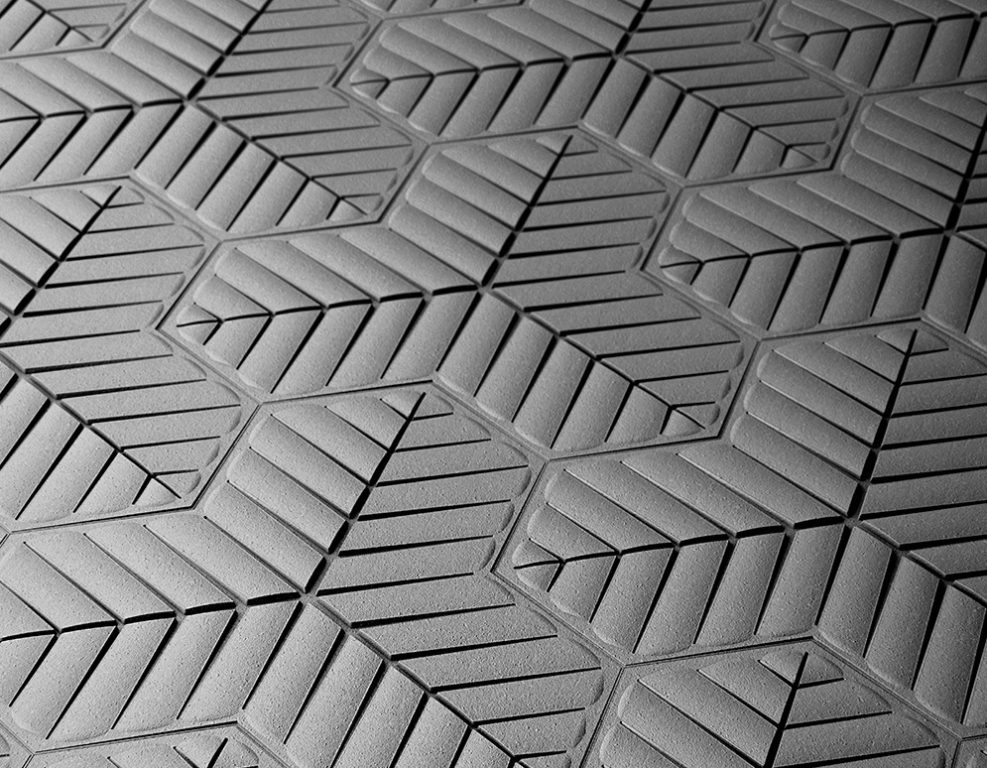

This technology has proved to be particularly vital when developing its latest masterpiece, the Trébol tile. Inspired by nature, this concrete brick is not only innovative and decorative but has been created to provide the perfect surface for pedestrian use, counting on excellent non-slip conditions as well as a comfortable surface.

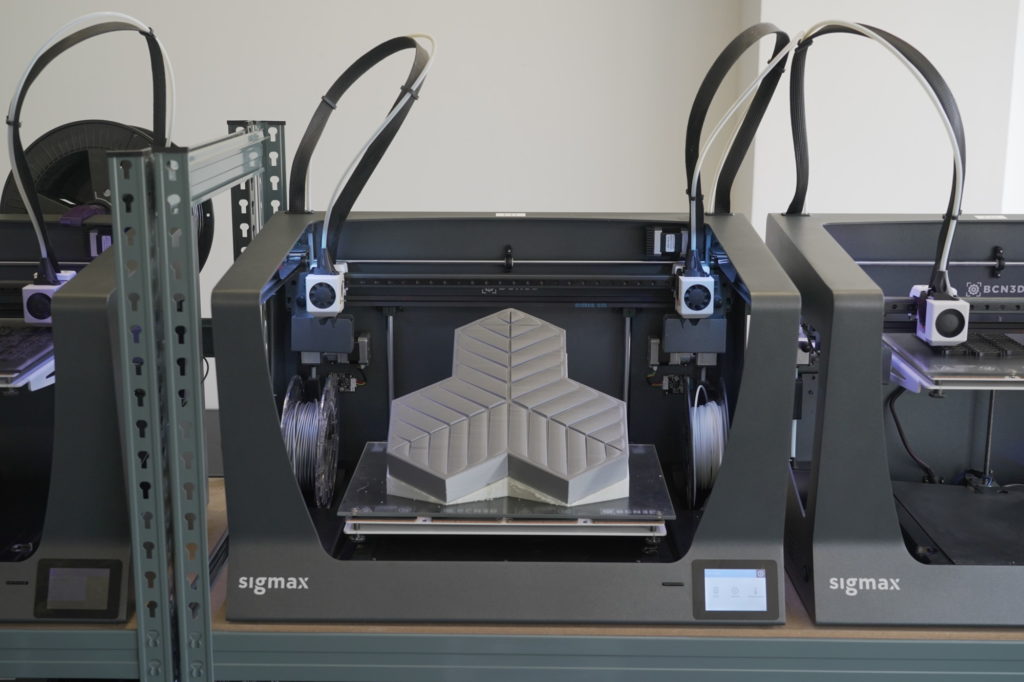

The iterative design process of this piece relied heavily on 3D printing. Using their BCN3D Sigmax 3D printer, several prototypes were fabricated “to validate aspects such as the dimensions, thicknesses, and measurements of the reliefs”, explains Gerard Arqué, Product Design Manager at Escofet. This is a crucial step in the validation process, since the tiles cannot only look good, they must also be functional. In the words of Arqué, the main benefit of counting on 3D printed tiles is that they “work as prototypes, from which we can draw decisive conclusions about the design”.

However, the advantages don’t stop there! In landscape architecture, tangible models are key, since they increase the three-dimensional understanding and facilitate for the designs to be communicated in a physical context. 3D printing allows these models to be fabricated quickly and at a low cost, as many models as necessary. These models are used by the commercial team to better transmit the design’s properties.

These are just the early stages of Escofet’s work with 3D printing, but the proficient results achieved on the Trébol tile project have shown to their Product Design team that this new technology is definitely here to stay.