Printing PET-G Filament: Temperature, Resistance, and Fil Comparisons

PET-G filament is one of the best 3D printing materials to use thanks to the combination of PLA’s ease of printing and the strength of ABS.

PET-G filament is a popular 3D printing material because it is easy to use while also being very technical. In this article, we’ll review the most important PET-G properties, as well as examine the differences of PETG vs PLA and ABS.

What is PET-G Filament?

PET-G (polyethylene terephthalate glycol-modified) is a commonly used thermoplastic 3D printing filament. It has a good balance of tensile strength and elongation, while also being water, heat, and chemical-resistant. On top of all of these qualities, this filament is also affordable and easy to print, making it a popular choice among many professional 3D printers.

PET-G Filament Properties

When printed, PET-G has a glossy surface finish, and a good level of resistance to abrasions. These characteristics make it an ideal material to use for end-use parts. Along with being aesthetically pleasing, this filament is also very technical. It is a tough filament that can withstand impact and is semi-flexible. It is very stable, and therefore an optimal filament to use if the print will be exposed to corrosive chemicals or water.

But all of this toughness doesn’t mean that PET-G is tough to print. In fact, PET-G is just as easy to print as PLA, making it a great option for beginners to 3D printing. This filament is also able to be printed with PVA supports.

PETG Filament: Temperature Resistance

- Extruder temperature: 240° C – 260° C

- Bed temperature: 90° C

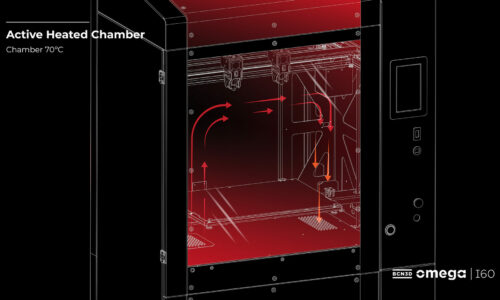

- Withstand operating temperatures up to 70°C

- PETG Melting point: 260° C

Common Uses for PETG Filament

PET-G lends itself to many different types of print applications.

Thanks to its water resistance, it is commonly used to produce parts that must be watertight or that will be exposed to moisture. Some common prints include bottles and containers that hold liquid and parts that must be waterproof.

PET-G is also a popular choice for chemically-resistant prints. If you are printing a part that will come into contact with salts, acids, and alkalis, then this filament could be a good option. PET-G can also be used for prints that will be used outdoors, as its combination of chemical, water, and UV resistance make it a strong option against the elements.

PET-G is also commonly used to create functional prototypes and tooling. Because it is a strong 3D filament, it can be used to print parts that must encounter high-stress applications, like snap-fit joints, jigs, and fixtures.

PETG vs PLA

PET-G and PLA are frequently compared to each other because of their share of similar properties. They’re some of the easiest 3D filaments to print. But, the similarities don’t stop there. Both filaments are thermoplastics, and they both have high tensile strength.

However, PETG is significantly more flexible than PLA. While PETG features an elongation at break of nearly 25%, PLA is very brittle, meaning it can break easily if pulled or bent.

PLA is one of the most cost-efficient 3D printing materials, with PET-G coming out as just slightly more expensive. It is also environmentally friendly and is biodegradable, while PET-G is not.

PLA is often used to create prints that have complex details or geometries. We can also use PLA to create prototypes, but if you need your prototype to be functional, strong, or heat-resistant, then PETG will be the better choice.

PETG vs ABS

Along with PLA, PETG is also commonly compared to ABS. While ABS used to be the go-to choice for a cost-effective yet strong filament, PETG is quickly taking the reins.

PET-G is much easier to print than ABS. It does not have as many issues when it comes to warping or the print not sticking to the bed. But, once printed, ABS prints are easier when post-processing, especially when it comes to painting and gluing.

PETG has higher tensile strength and higher elongation (about double) than ABS, but ABS has higher impact strength. ABS has a higher resistance to high temperatures than PETG.

Conclusion

PET-G is a great 3D printing material to choose if you need a filament that will be high-strength, durable, and able to withstand the elements while also being cost-effective and easy to use. Don’t overlook this versatile 3D filament!