PLA vs ABS: Which 3D Filament is Better?

PLA vs ABS or ABS vs PLA? These are two of the most commonly used 3D printing filaments.

So, how should you decide between the two when planning a print? While PLA and ABS filament are both very popular, they both have unique properties that make them ideal for different projects.

In this article, we’ll explain the main differences of ABS vs PLA, and break down their diverse properties and uses.

What is PLA?

Index

PLA stands for polylactic acid. It is a sustainable 3D printing filament made from organic sources. As one of the most commonly used 3D printing materials, PLA filament is popular due to its ease of use and lower price point.

PLA is a standard filament that features an opaque, glossy finish and is commonly used for complex and detailed prints. PLA filament is a great starter material for beginners. This material is commonly used for prototyping and architectural mockups as it can print difficult or complex features.

What is ABS filament?

ABS, which stands for acrylonitrile butadiene styrene, is a thermoplastic filament. As opposed to PLA filament, ABS is a bit more technical and may be more challenging for new 3D printing users. ABS is a stiff 3D printing material and it is impact and heat resistant. Common applications for ABS include end-use tools, moving parts, and parts that have to withstand high mechanical stress.

ABS vs PLA Properties

Both ABS and PLA have unique properties and applications. Let’s get a bit more specific.

ABS vs PLA Uses

- While PLA and ABS are both plastics, they are often used for very different applications. ABS is often used for engineering and manufacturing purposes as it is a rigid material that can withstand high impact. Its durability makes it common for end-use products, especially as protective cases, like on suitcases or phone cases.

- PLA is a popular filament for prototypes. It is great for understanding the visual and aesthetic properties of prototypes, especially when it comes to small, complex details. PLA filament is also commonly used by beginners who are getting familiar with the world of 3D printing. It is also odorless, making it a suitable fit in an office or school environment.

- PLA does best in projects that are not mechanically or thermally demanding, as it has low solvent and water resistance. This means that PLA is perfect for concept models, casting molds, and mockups. It allows you to visually compare different designs without burning through your wallet or creating a burden on the Earth, as PLA is biodegradable.

- If you need the prototype to be strong or technically functional, opt for using ABS. ABS is better suited for more technical applications and moving parts.

Is ABS stronger Than PLA?

When it comes down to the strength of both materials, ABS filament is definitely the winner. ABS is stiff, impact-resistant, and durable. It can take a blow or vibrations much better than PLA can. Even at lower temperatures, ABS has a higher impact resistance than PLA. ABS is also more water-resistant than PLA.

PLA tends to be more rigid and fragile. However, PLA filament does have good UV resistance and good tensile strength. Both PLA and ABS have a lower resistance to solvents, as compared to other filaments.

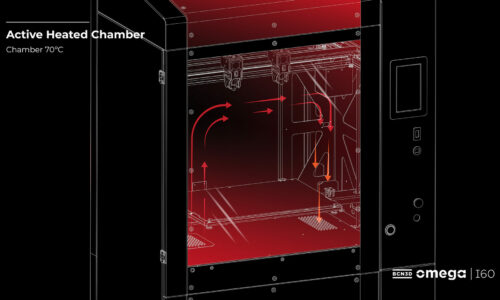

PLA vs ABS Melting Temperature

PLA can withstand operating temperatures of 50°C and has a glass transition temperature of 57°C. Generally, PLA is not able to withstand high temperatures. On the opposite hand, ABS has a much higher temperature resistance. As it is amorphous, it does not completely melt, but it has a glass transition temperature of 80° and 114°C.

Final Thoughts regarding ABS vs PLA

Ultimately, when it comes down to choosing ABS vs PLA, your final decision will always depend on your reason for printing. If you are a beginner at 3D printing or need to print detailed projects that don’t require a lot of functionality, consider PLA.

On the other hand, if you need a material that can withstand impact and is highly functional, ABS will be the best option of the two. Each filament has its own unique strengths that make it ideal for certain types of projects.